Problem: Plastic strain results do not match with the Von Mises stress results.

Hi all,

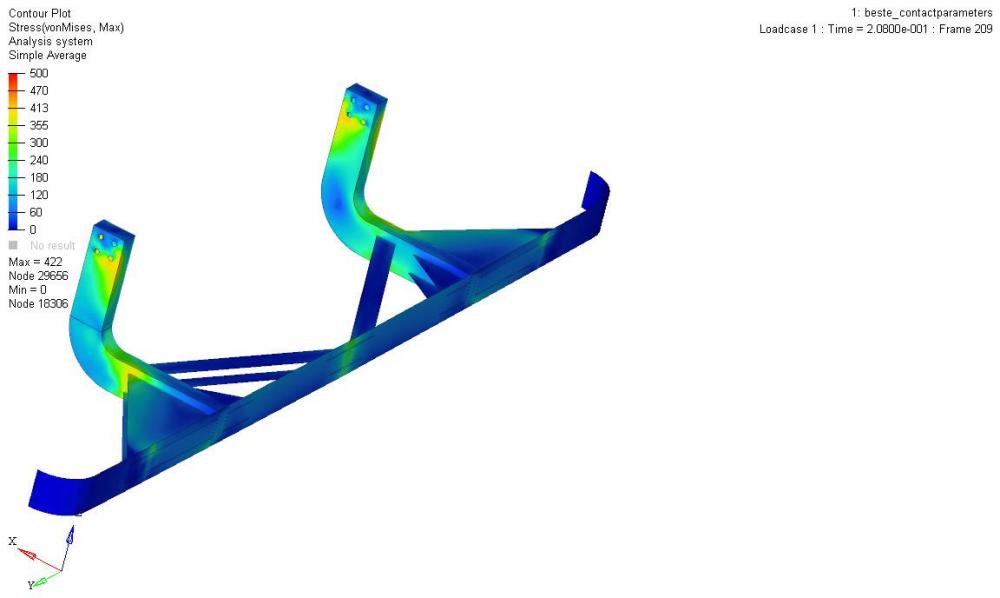

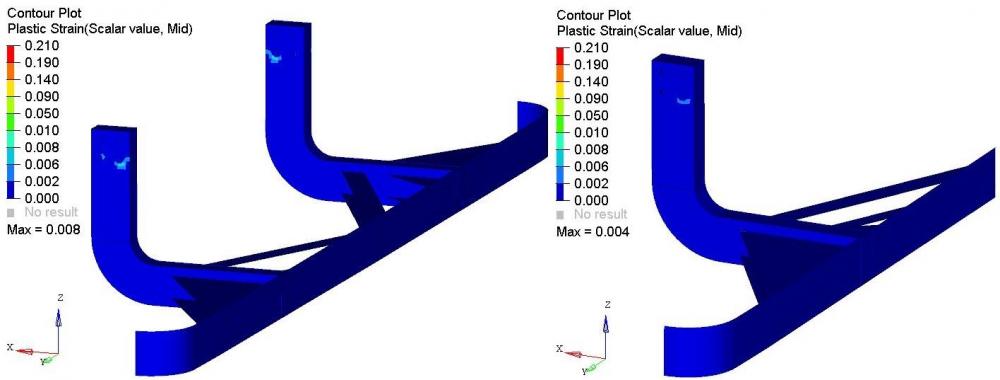

I'm getting very low plastic strain results in my simulations. the Von mises stress (422 MPa) clearly passes the yield point (355 MPa), however plastic strain only reaches a value of 0,008. This Von mises value approaches the UTS value of 455 MPa, the strain at uts is defined as 0,09. Can someone please explain to me how i can solve this, or explain why this is happening?

<?xml version="1.0" encoding="UTF-8"?>

Find more posts tagged with

Hi Andy,

Thank you for you're response and insight.

So it could be that the plastic strain of 0,008 is realistic. When I calculate the stress with the JC formula, I get a true stress value of 435 MPa at a plastic strain of 0,008. Which could match the true stress strain plot.

Could you tell me how the Plastic strain is calculated for post processing purposes?

Thanks,

Cedric

Hi,

With LAW2, Iflag=1 the UTS and strain at UTS are engineering strain values. But the output by Radioss is true stress and strain. If you look in the Radioss starter you can see the Iflag=0, a, b, n values that are calculated using your input.

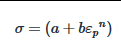

JOHNSON COOK MODEL : YIELD STRESS . . . . . . . . . . . . .= 355.0000000000 ULTIMATE STRESS (UTS) . . . . . . . . .= 470.0000000000 STRAIN AT UTS (Ag). . . . . . . . . . .= 9.0000000000000E-02 YIELD COEFFICIENT A . . . . . . . . . .= 355.0000000000 YIELD COEFFICIENT B . . . . . . . . . .= 312.9879880695 YIELD COEFFICIENT N . . . . . . . . . .= 0.2806664576242 EPS-MAX . . . . . . . . . . . . . . . .= 0.2100000000000 SIG-MAX . . . . . . . . . . . . . . . .= 1.0000000000000E+30 ISO-KINEMATIC HARDENING FACTOR. . . . .= 0.000000000000You can input the a, b, n value into the equation in the comments of LAW2. Note this equation is true stress as a function of plastic strain and I have left off the temperature and strain rate terms.

Note this equation is true stress as a function of plastic strain and I have left off the temperature and strain rate terms.

Or the pre-processor HyperCrash lets you plot a material when you use a, b, n in LAW2.

Note that this is a plot of True stress versus true strain (not plastic strain).

Please check if your output makes better sense using these stress strain plots.

It is good that you are thinking about the results with respect to your material input to see if they make sense. Not everyone does this but they should!

Thanks,

Andy