Hello,

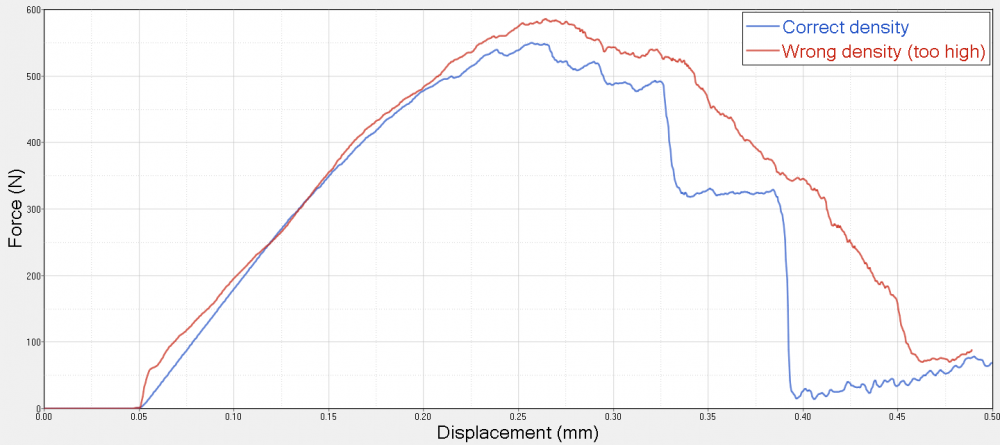

I am simulating a pull out test of a screw from an elastoplastic material ( MAT_LAW2, PLAS_JOHNS). The imposed displacement velocity that I apply on the screw is a lot higher than in reality. Before I used an elastoplastic material with a much higher density (probably like an excessive mass scaling) than the real one because it speeded up the simulation and the results did not change a lot.

When I now perform the simulation with the correct density, I obtain curves which have sudden drops after the maximum force (see figure attached) is reached and from the .h3d file it seems that this is caused by a simultaneous deletion of many elements on one side of the screw.

I do not think that this latter behavior is correct and I wanted to know if someone has a suggestion on why this is happening. Can it be due to dynamic effects? What is the role of the density in the computations?

<?xml version="1.0" encoding="UTF-8"?>