Hey guys!

I made a tutorial of composite optimization which contains a ply smoothing steps. The name of the tutorial: OS-T: 3400 Design an Open Hole Tension (OHT).

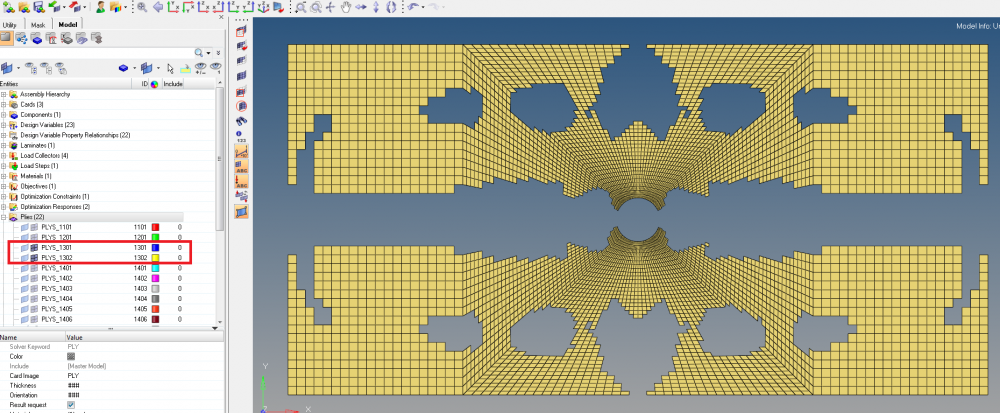

The model setup was the same and I got the same result for linear static analysis just like in the tutorial. The optmization went well, I got the same result as you can see on the attached picture. In the tutorial the name of the plies are different because I use the version 2017.2 . I have 2 plies which contain the same element like in the tutorial.

<?xml version="1.0" encoding="UTF-8"?>

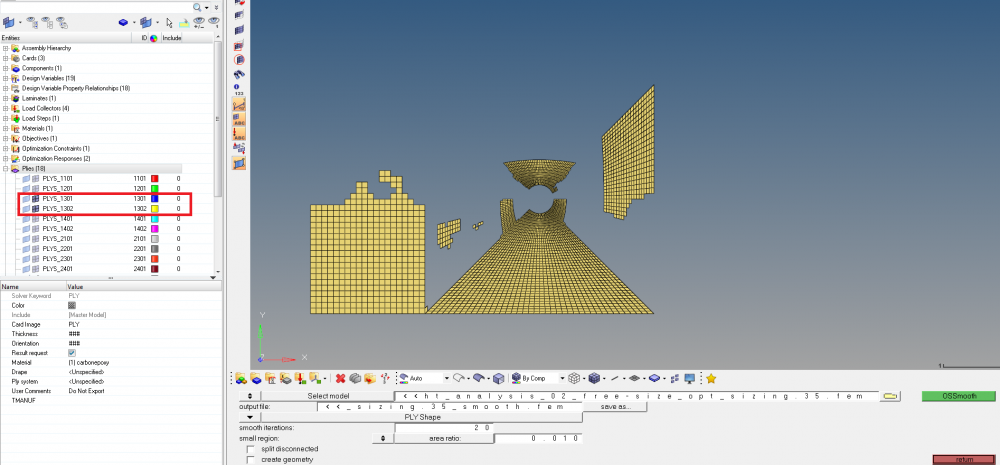

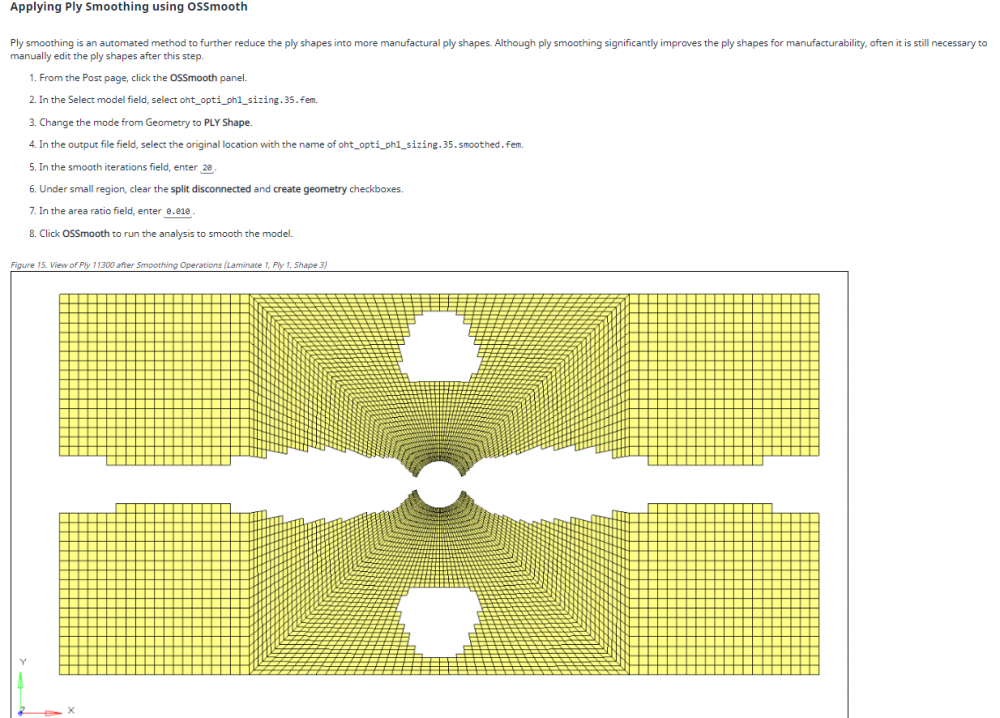

After free-size optimization I made the next step: OSSMOTH. It gave me some funny result as you can see on the pictures. You can see the settings are the same and the results still different.

<?xml version="1.0" encoding="UTF-8"?>

On the 3rd picture you can see the OSSMOTHING result from the tutorial. You can see that the settings are the same but the results are very different.

<?xml version="1.0" encoding="UTF-8"?>

Could someone explain why I got so different result?

Thanks for your answer in advance!

Best regards,

Imre