Hello,

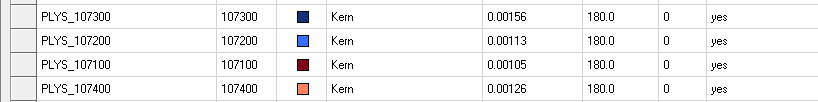

I've run a free-sizing optimization on a formula student monocoque. I set some parameters for the core material, for it to be max 12.5mm and in steps of 2.5 mm manufacturibility.

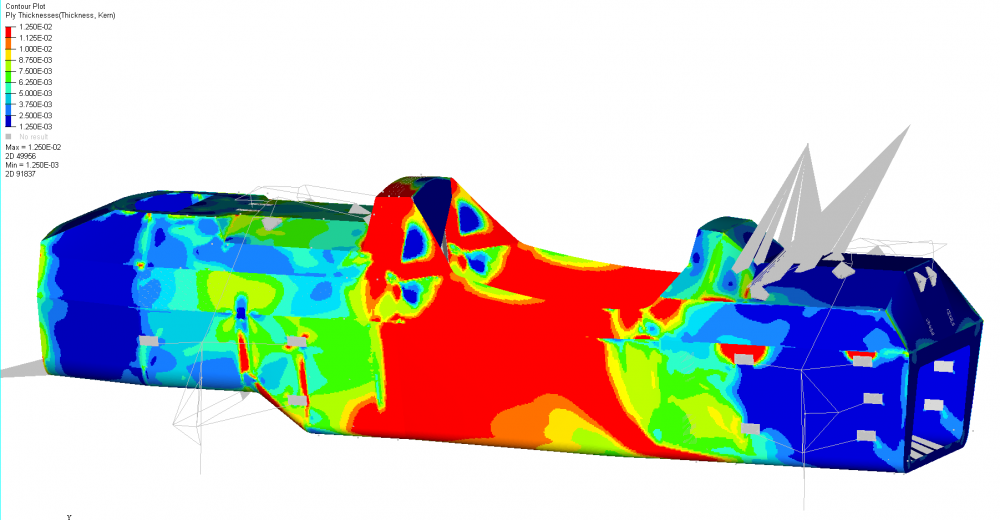

When I have a look at the xxx_des.h3d I can see that the thickness of the core in some areas is 12.5mm (my model is in meters).

However, when I import this model into a new model (with import-solver deck), the thickness of the core plies are not even close to 12.5mm in total. What is causing this behaviour?

I attached 2 pictures to clarify.

Thank you in advance

Alex

<?xml version="1.0" encoding="UTF-8"?>

<?xml version="1.0" encoding="UTF-8"?>