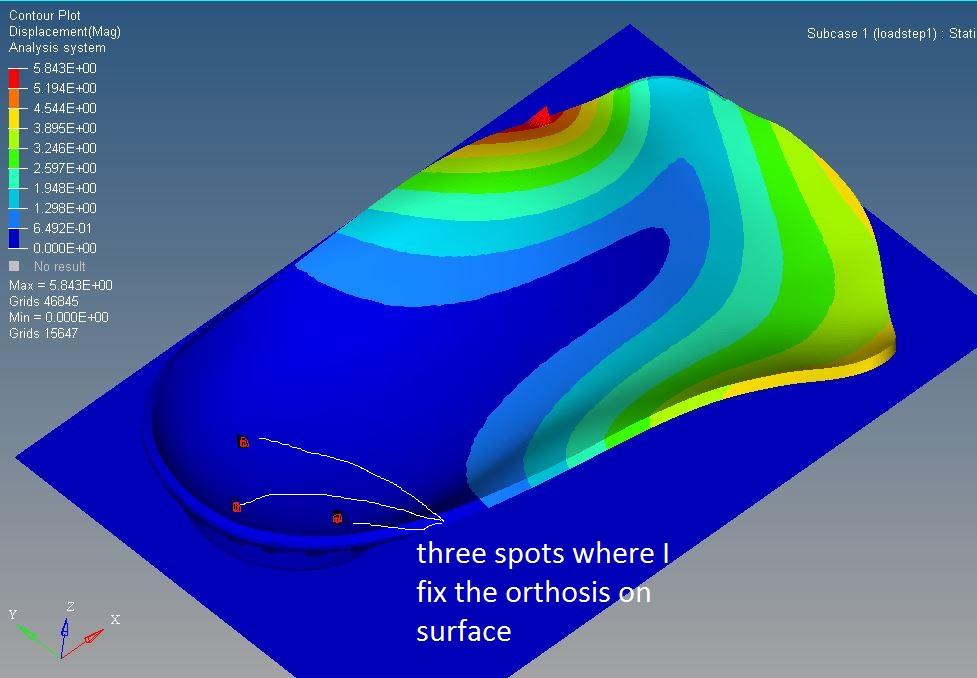

I am recently using Optistruct to validate the displacements of FE model with the experimental results. I have a foot orthosis in my set-up which has some holes in the back. I fix three holes with three nails on the back (as in the figure), and I apply load to foot orthosis. I control the value of loading with load cell to apply the exact value of loading in FE model, and also the loacation oif l;oading with tracking markers. To model the nail constraint, I fix three nodes instead of modelling a the nail fixation. However, when I fix all degrees of freedom, my displacement is much less than experimental model (half of real displacement). I also try to just fix the displacement not rotation, but my model rotates a lot. Can somebody tell me what is the best approach to model such constraint to be more realistic?

Thanks,

Maryam

<?xml version="1.0" encoding="UTF-8"?>

<?xml version="1.0" encoding="UTF-8"?>