Altair® EDEM™ 2025.1 introduces powerful updates for advanced particle simulation. In collaboration with Granutools™, we have extended the EDEM calibration kit to allow users to automatically run and post-process simulations based on the well-known GranuHeap and GranuDrum standard tests, thus reducing the time and effort required for material model calibration of powders for advanced Discrete Element Method (DEM) applications such as battery manufacturing, pharmaceutical and process manufacturing, playing a key role in Automotive Electric Vehicles (EVs), Consumer Electronics and Healthcare verticals.

To continue the advancements in optimization and simulation-driven design, we have added a new model capable to analyze collision energy during the simulation of processes where this information is relevant, like milling applications for mining and process industries. Continuing the work from previous releases, we have added new improvements to our custom model API, increasing its capabilities to develop more complex physics models that are fully integrated into EDEM.

Here are some more details of the key highlights from this latest release now available on Altair One!

Industry-grade Powder Flow Calibration

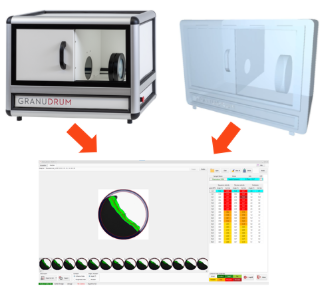

In collaboration with Granutools™ we have extended the EDEM calibration kit to allow users to automatically run and post-process simulations based on the well-known GranuHeap and GranuDrum standard tests, thus reducing the time and effort required for material model calibration of powders and to achieve industry-grade powder flow calibration for their simulations.

Ganutools is very well known and recognized within the industry and Altair is delighted to be embarking on this technology partnership. This is a key capability for EDEM as it will simplify and improve the workflow for users who already use Granutools independently and for others who can add it to their tool set to enhance the realistic representation of the real-world behavior for powders.

“This new release is a major step forward for Altair EDEM users with Granutools digital twins. Material calibration is now based on dynamic physical measurements, including environmental conditions like temperature and humidity. The performance of these digital twins increases with Granutools simple instrument geometries and Granutools’ unique technology — featuring strict initialization protocols for better user independence as well as precise and repeatable measurements.”

Filip Francqui

Managing Director, Granutools

The GranuHeap instrument measures the static angle of repose of a powder heap. The addition of these numerical tests in EDEM will enable users to understand how different powders naturally pile up when poured which is useful for storage, packaging and handling applications. Users will gain insight into powder flowability, cohesion and inter-particle interactions and allow them to understand how a powder behaves at rest.

The GranuDrum instrument measures dynamic flow properties of powders. The addition of these numerical tests in EDEM will enable users to understand more about the behavior and flow stability of their powder which is useful for processing and manufacturing applications. Users will be able to measure the dynamic angle of repose and determine the cohesive index of powder and allow them to understand how a powder behaves while in motion.

New Model for Energy Analysis of collisions

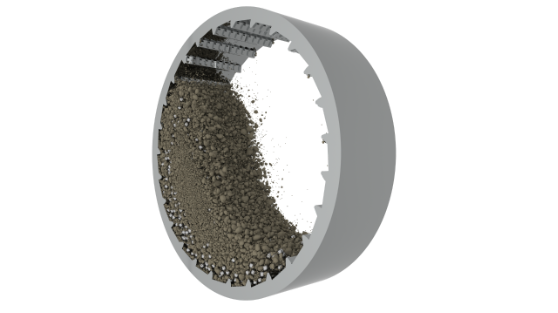

To continue the advancements in particle simulation, we have released an innovative model to track the energy loss from particle collisions during simulations. This is particularly useful for milling applications across mining and process industries.

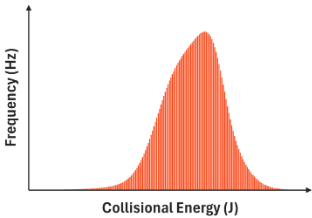

The ‘Collisional Energy Tracking Model’ is a new contact model that allows tracking and statistical analysis of the energy dissipated in collisions during a simulation. The model records data for dissipated energy in a similar manner to the 'Track Collisions' option that is already available in the Simulator, only this model is compatible with both CPU and GPU simulations. The output of the model is stored statistic data in the form of counter properties that keep track of collision counts and energy losses for both particle-particle and particle-geometry collisions. Users will be able to analyse collision energy to optimize mill grinding efficiency and track particle damage and erosion. The graph below shows an example of the collisional total energy loss distribution for a milling case:

Liquid Bridge Model Improvements

This model was first introduced to allow a unified force between particles or particles and a geometry when they are wet.

Now, the mass of the particle can be updated without changing the particle size. Users will be able to achieve better representation when the material is slightly wet or partially saturated and benefit from greater accuracy and an improved workflow.

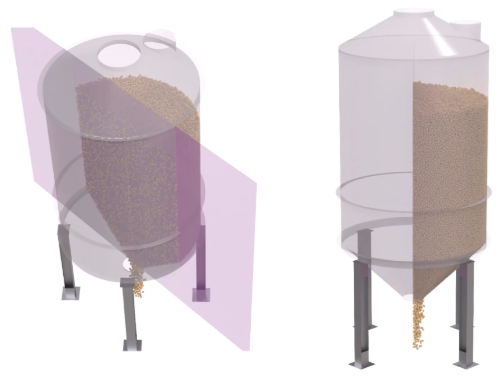

Improvements to Cylindrical Periodic Boundaries

Users had requested to reduce some of the restrictions when measuring different behaviors in the cylinder for applications such as blast furnaces, large hoppers, and powder delivery devices. Users can now achieve a simplified setup for faster analysis and design, and benefit from reduced computational cost for systems that have rotational symmetry.

It is no longer necessary to prevent particles from reaching the centre of the cylindrical domain, and the angle limit has been increased to 180 degrees. To support this, a new option 'Enable Self-Contacts and Double-Mirroring' has been added to the cylindrical periodic boundary settings. This feature should be enabled by default when using the GPU solver and will be enabled in general for new setups.

What else?

Beyond these new capabilities and improvements, this release also brings other important developments, including:

Improved DEM-CFD Workflow using SimLab

Users can now set up the full DEM-CFD coupled simulation and complete pre- and post-processing including visualization directly within the SimLab interface.

This means that the complete EDEM- AcuSolve (for CFD) coupling can be performed in a single interface.

API Updates for more complex contact models

Following the work from the previous releases, we have continued the evolution of our custom model API, considerably improving the capabilities to develop more complex physics models that are fully integrated into EDEM.

Some of the improvements and additions to the API are the capability to scale the particle mass independently of the volume, access to material information, Field data available for CUDA, and generation of custom warning and error messages during setup.

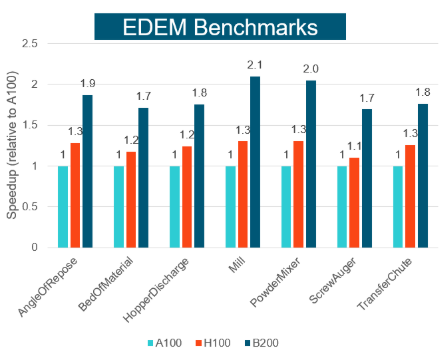

Market-leading Performance with NVIDIA

To enable best in class performance, EDEM is available to run on the latest hardware from NVIDIA including the new NVIDIA DGX™ B200. Initial benchmarks have seen up to a 2X speed up compared to running on the A100 card. Another key benefit is that the B200 card is optimized for use with AI keeping EDEM at the forefront of simulation and AI.

To find out more about what is new in EDEM 2025.1, check out the release notes that are available on Altair Marketplace: here