Hello,

I am exploring different optimization setups for a model with a unique load case which consists of:

- SPCs → coming from enforced displacements (that is nonzero SPCs)

- Mechanical Loads → bearing loads

- Thermal Loads → different temperatures in whole model

My first thought was that a minimize Compliance objective would output bad results, as compliance has opposite behaviour in stiffness for applied forces (first formula) and applied displacements (second formula).

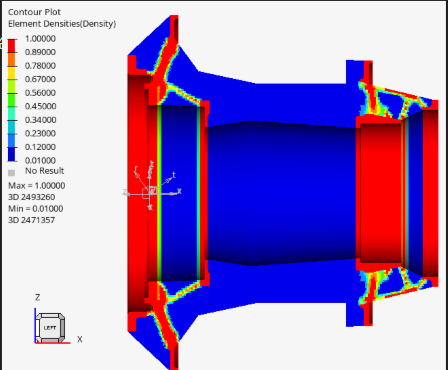

However, the densities countour looks like this:

That is a good optimization result with a Discretness index of 0.49 and a 0.15 design volfrac constraint achieved. I have also reviewed the .asens files and the sensitivies for the compliance response are both negative and positive across the elements.

I wonder how is the software counting for both compliance formulations in the sensitivities calculation.

Thanks.

Kind regards,

Alfonso