In Additive Manufacturing (via Binder Jetting, Metal Injection Molding, Metal FDM, Ceramic FFF, and many more similar processes), sintering is a critical step where parts are heated to near-melting temperatures to bond particles together. But during this process, a common challenge arises—part lift.

Part lift refers to the upward warping or deformation of a part as it sinters. This can be caused by uneven shrinkage, thermal gradients, or poor support design. If not controlled, the parts can topple in the oven, dimensional inaccuracies and failed parts.

By predicting and correcting part lift, manufacturers ensure better quality, improved yields, and more reliable parts—especially in high-precision industries like aerospace and medical devices.

Inspire Print (Sintering) can help predict part lifting during the sintering process.

Here is how you do it:

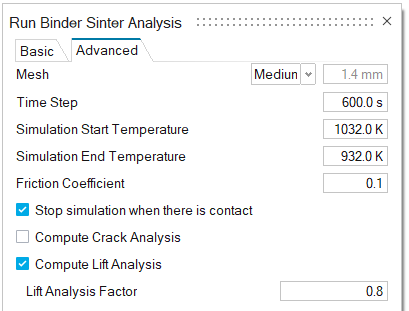

- Turn on the Compute Lift Analysis check box in the Run analysis window.

- Specify "Lift Analysis Factor" between 0 to 1.

- 0 : This means the part will not lift from the base plate. This is as good as turning off

- 1 : maximum lifting part from a base plate.

- Finetune the parameter based on the material and machine used for sintering.

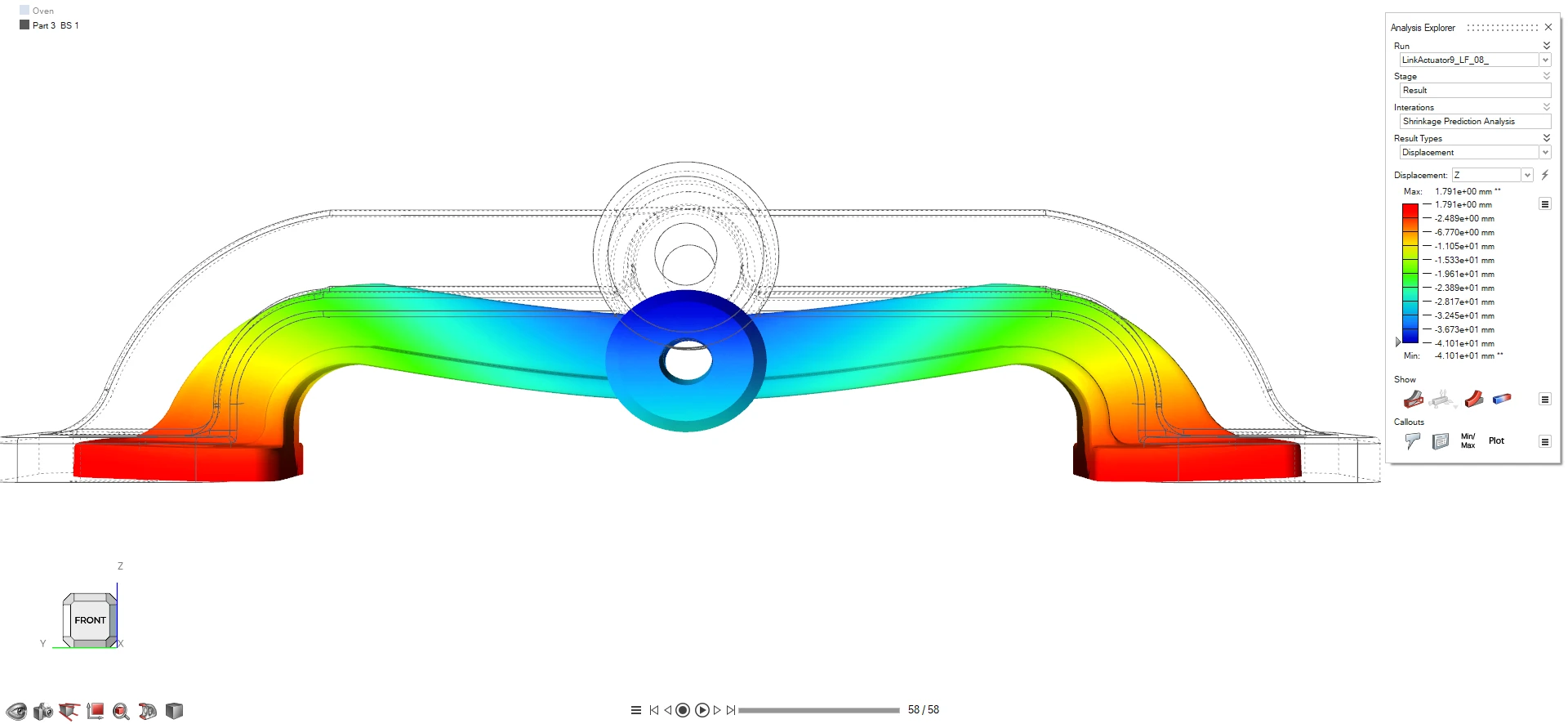

Effect of LiftAnalysisFactor values:

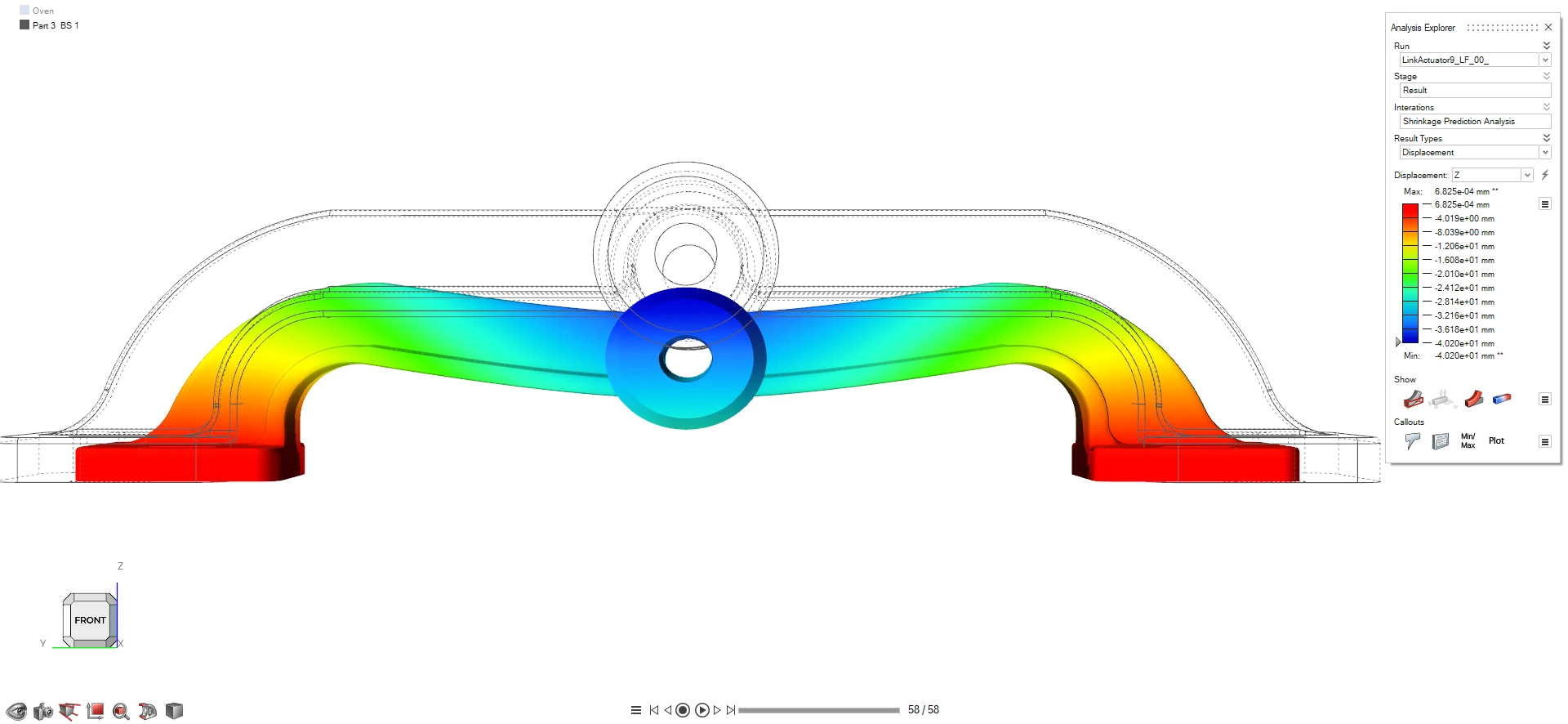

- LiftAnalysisFactor = 1.0

- maximum part lifting from the base plate.

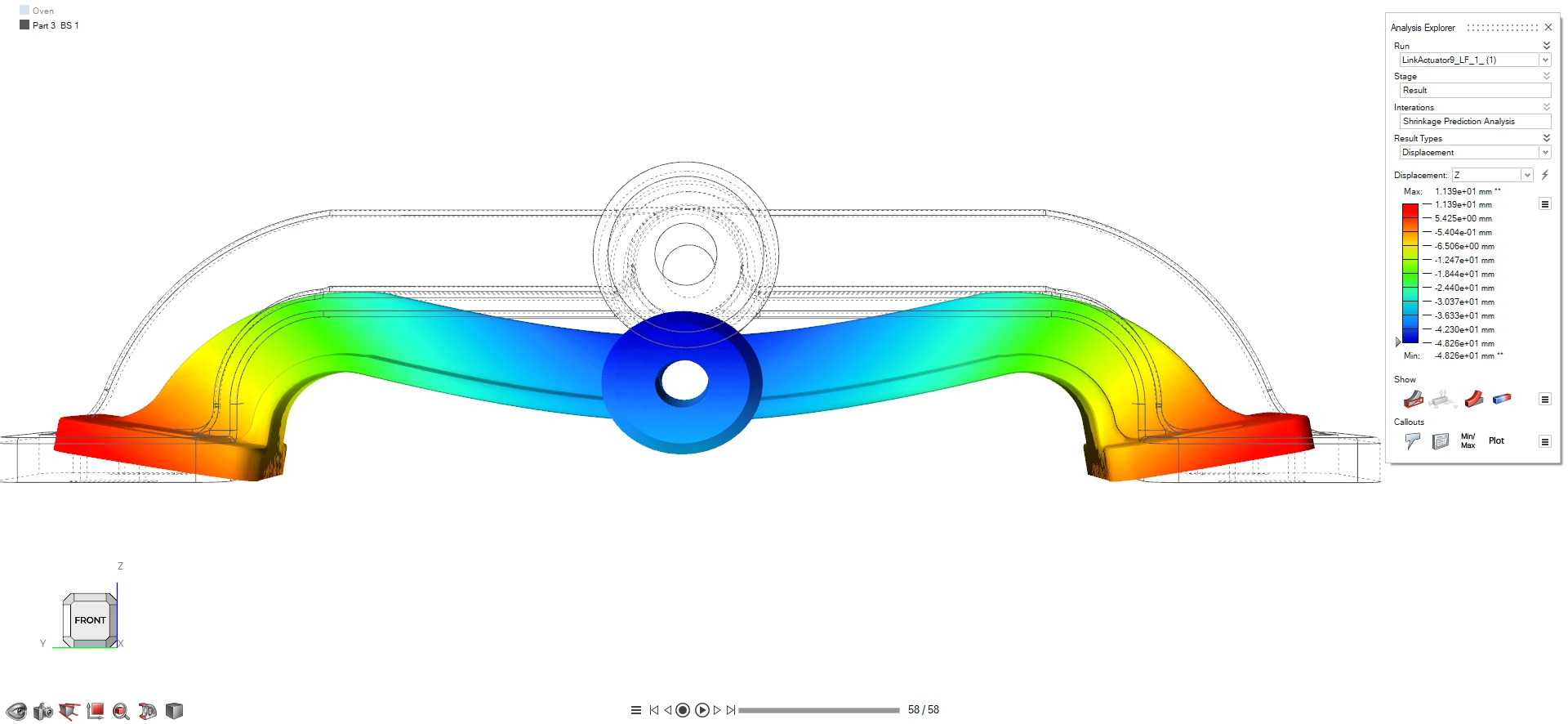

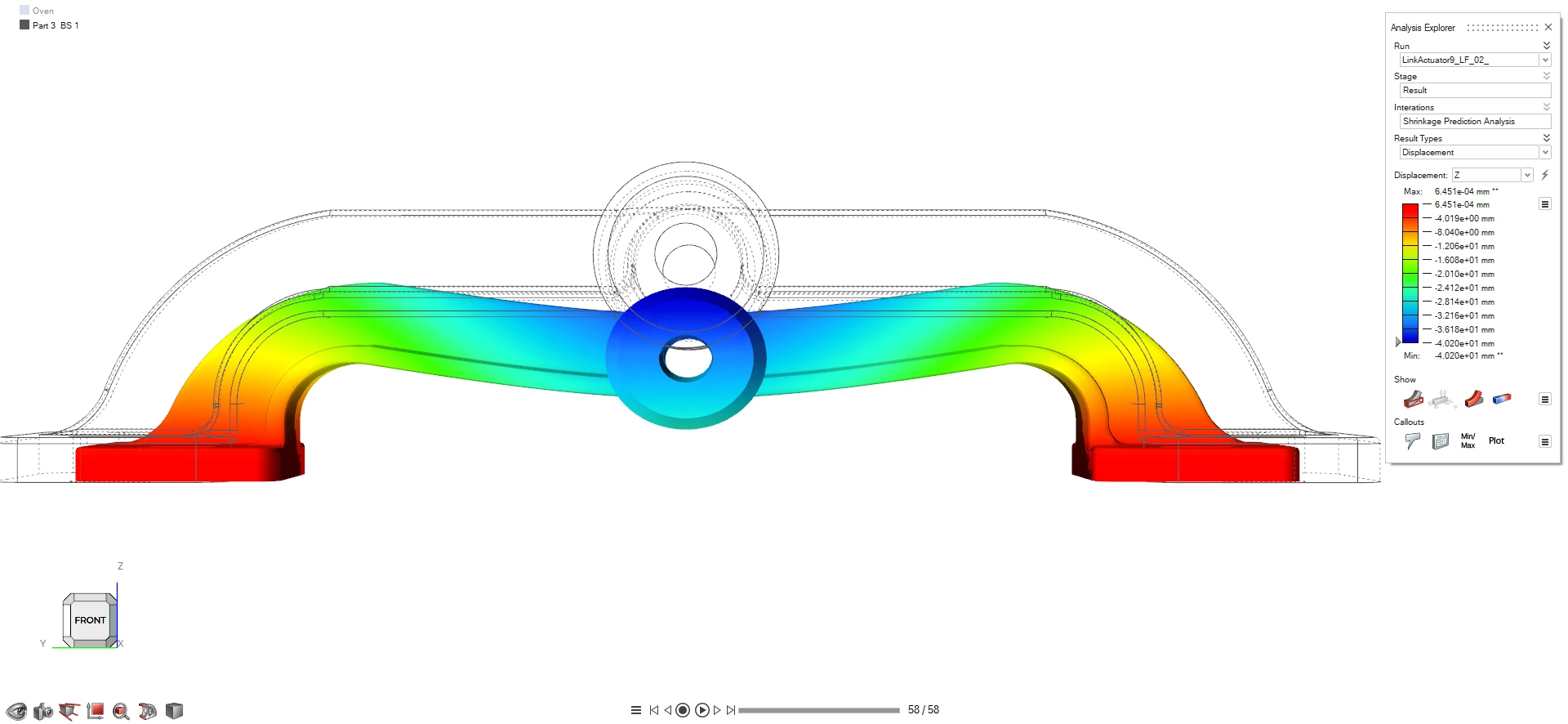

- LiftAnalysisFactor = 0.8

- ListAnalysisFactor=0.2

- LiftAnalysisFactor = 0.0

- no lifting of part from the base plate. This is as good as turning off list analysis.