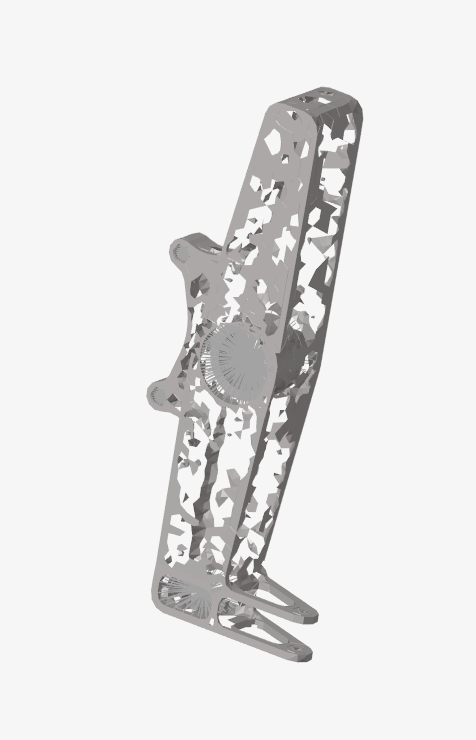

I am trying to optimize a part so that the material removed will be through holes only in one plane ie a consistent cross section. I thought that the way to achieve this is through an extrusion or a draw, but the optimization results are random nodes with some just floating in free space. In the design variable, I have set an extrusion along the depth of the part and also a mindim of 15, which should be 3 elements. I am unsure if this is being achieved as well.

Thank you for your help.