Abstract: Additive Manufacturing (AM) techniques are being adopted in the commercial production of parts and are becoming the future of the manufacturing industry. These processes differ based on the material type, material feedstock, the state of fusion, the energy source of fusion, and the AM principle. Among these methods, metal Binder Jet Sintering (BJS) is finding a prominent role due to its energy efficiency and low operation cost. However, it comes with significant challenges, such as meeting the dimensional tolerance requirements, density variation of the printed part, and potential cracking during the debinding stage. Part designers have to design the green part to meet the desired dimensional tolerances after shrinkage during the sintering process. Since this shrinkage is a nonlinear phenomenon, correcting it requires a trial-and-error approach. The local relative density increase is also driven by the same process mechanism and predicting this variation in the part geometry is critical for the part quality. These challenges require accurate numerical simulation of the BJS process to predict the final part dimensions, density distribution, and other part quality issues. This becomes the basis for the shape correction of the green part to meet the final dimensional requirements.

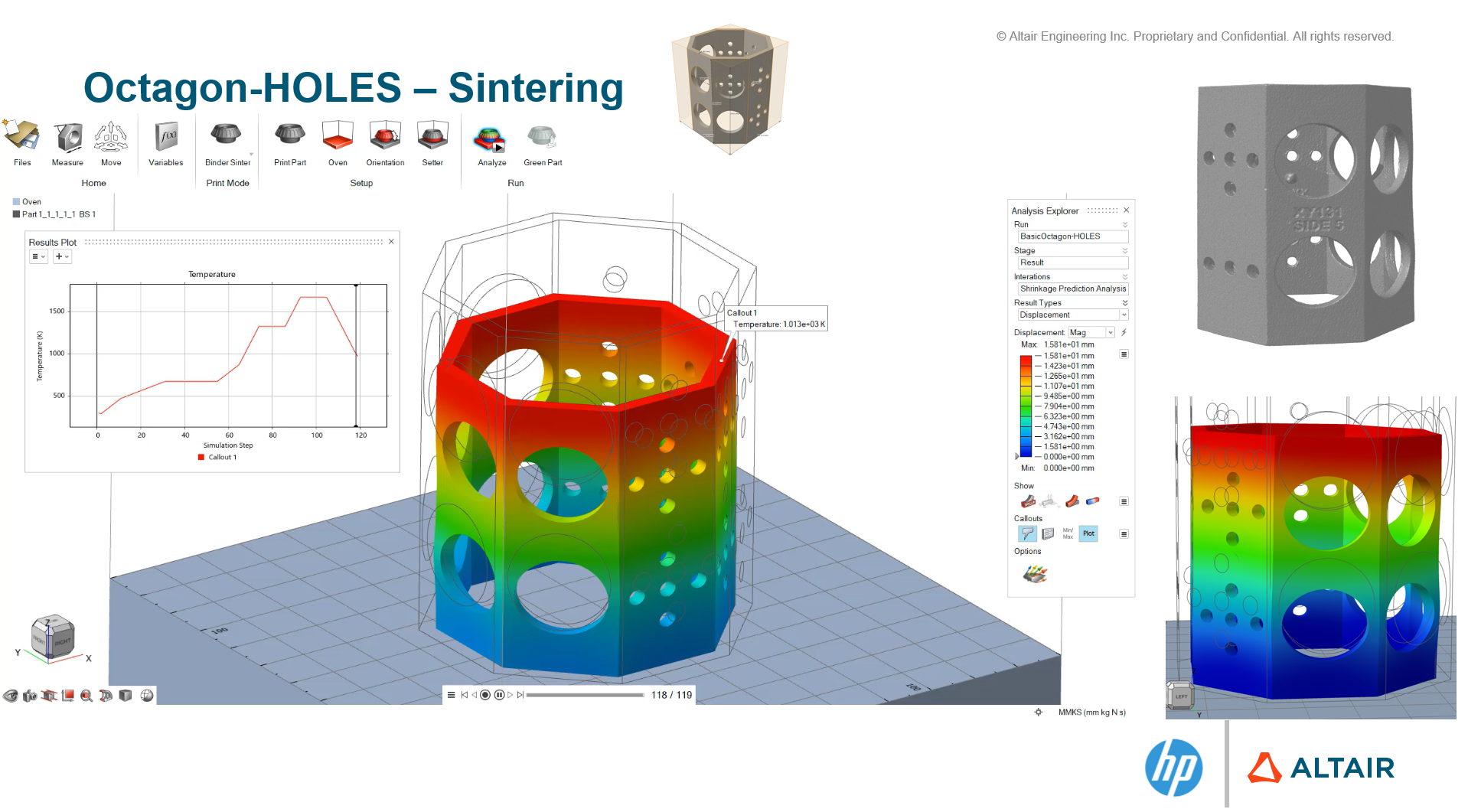

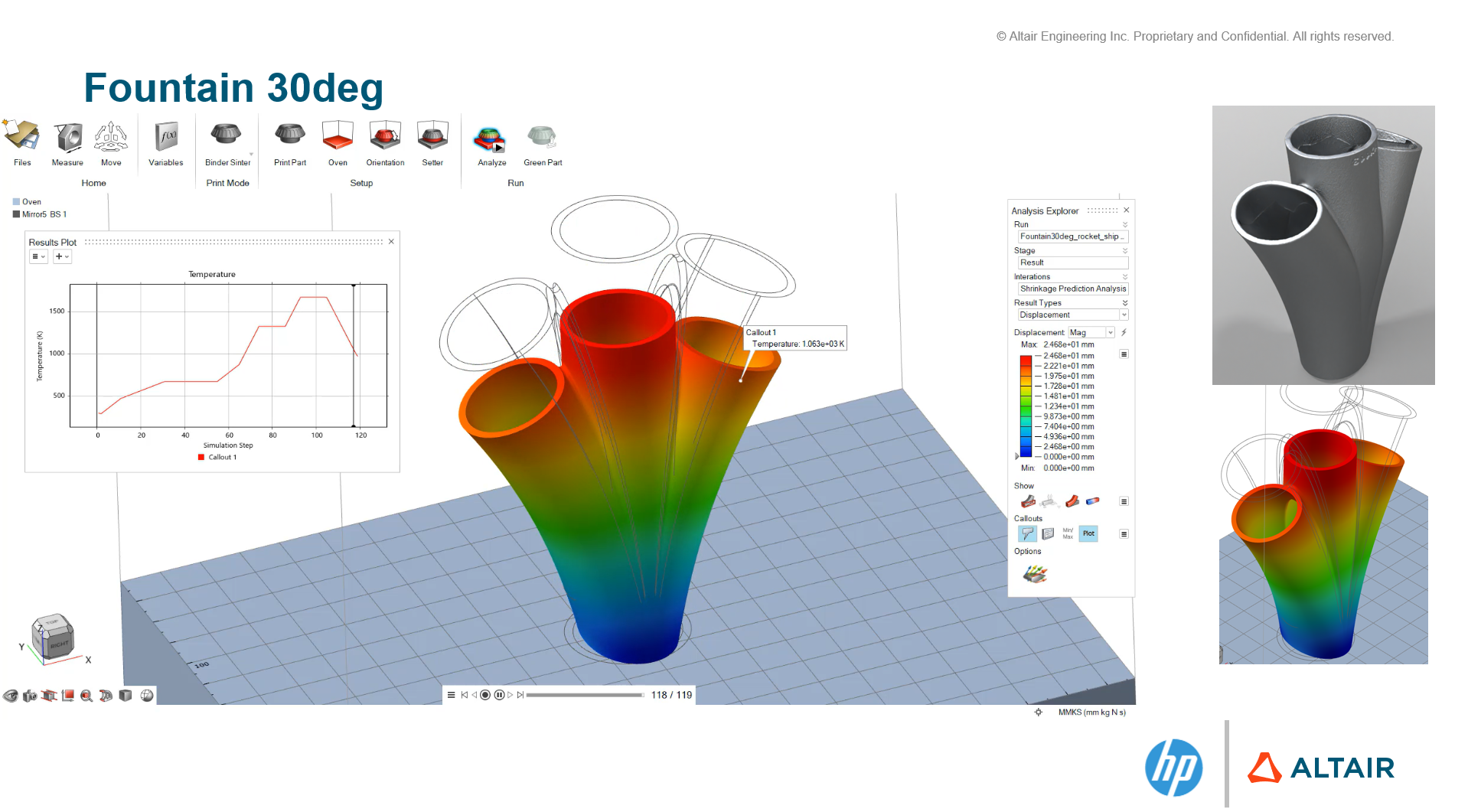

A transient finite element solution to model the BJS process accurately is presented in this work. The laws of conservation mass, momentum, and energy are solved with the models for material behavior and sintering stress. The sintering process is driven by the reduction of free energy by forces associated with the curvature of the particle surface, any applied external pressure, and chemical reactions. The governing equations are written in terms of relative density, and we consider the effects of thermal, elastic, viscoplastic, and sintering stress. Two different material models – the powder Skorohold-Olevsky Viscous Sintering model and the two-phase densification models are studied in this work. For improving computational efficiency, the method developed can model the entire or partial oven curve, and in addition, it can be done either by imposing the temperature or by computing it using the energy equation. The numerical simulation includes grain growth prediction using Arrhenius models. The computed transient results include relative density, temperature, sinter deviation, shrinkage, and grain size. The predicted results presented are validated using experimental data to enable its use for compensation analysis.

The shape compensation analysis is achieved through an iterative solution methodology. It starts with a sintering analysis of the part under the specified conditions using the initially designed geometry, based on the predicted shrinkage and distortion the green part geometry is automatically adjusted and solved again. This process is repeated until the desired tolerance is achieved. The results and validations are presented to demonstrate the accuracy and practical utility of the solution presented in designing and manufacturing parts using 3D printing with a binder jet sintering process.

Authors: Pavan Suri(HP), Narendra Singh(Altair), Ravi Mayavaram(Altair)

Presented at: MIM 2025 Conference

https://www.mpif.org/EventsCourses/MIM2025/MIM2025Schedule/MIM2025Abstracts.aspx

Highlights: Inspire Print addresses the increasing demand for sintering simulation in additive manufacturing. Sintering offers several benefits in 3D printing, including:

- Avoiding melting

- Lower energy consumption

- Capability to produce large and complex parts

However, accurate shrinkage prediction and compensation are critical for successful implementation. The sintering simulation in Inspire Print3D utilizes constitutive models, specifically Skorohod-Olevsky Viscous Sintering (SOVS) and Two-phase models, to predict material behavior during the sintering process. The software incorporates multiple grain size models, which are crucial for accurately simulating microstructural evolution during sintering.

Key Features of Inspire Print Sintering Simulation:

We would like to express our gratitude to HP for sharing the part geometry and experimental results with Altair.

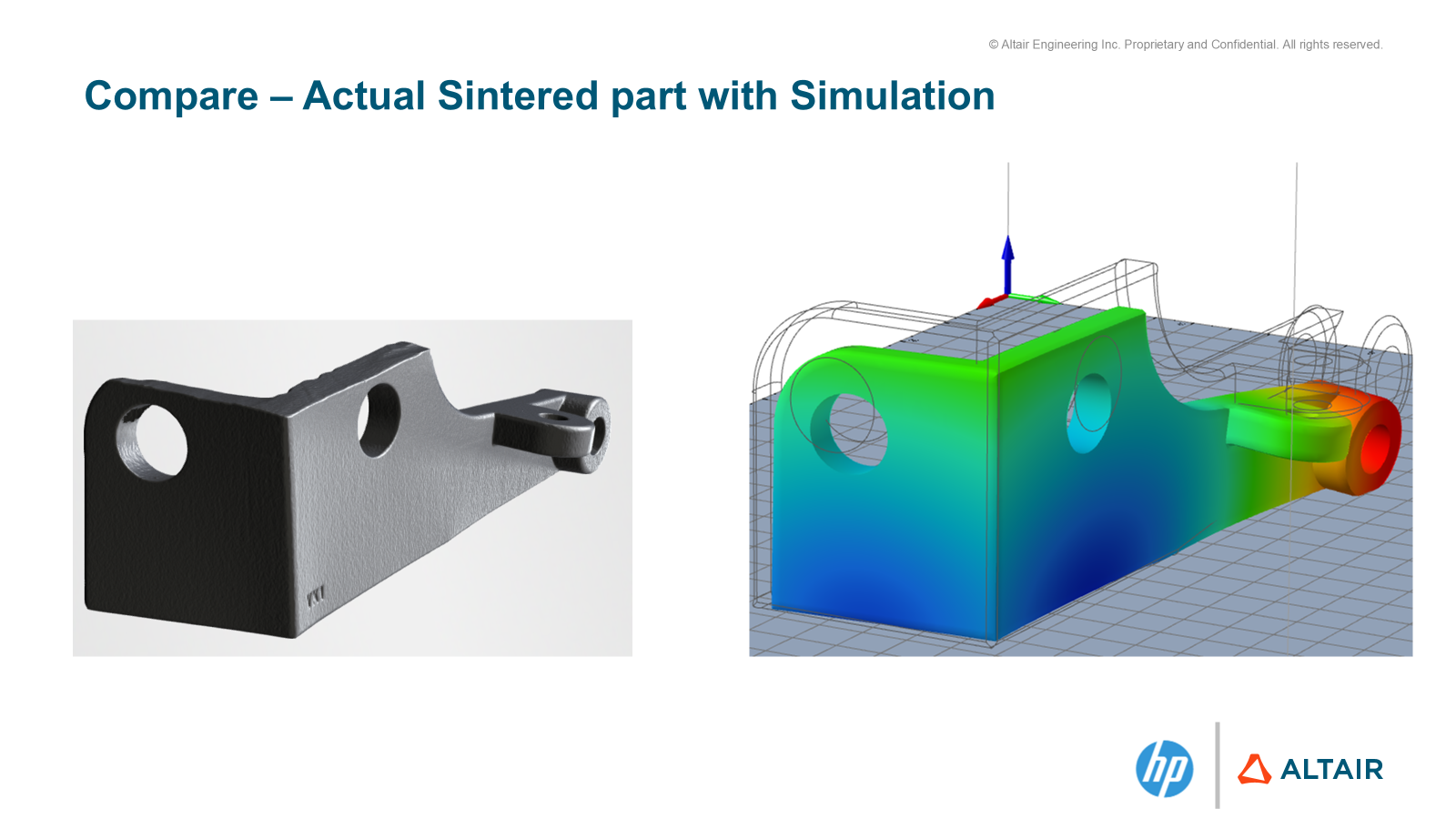

Part: Bracket

Part: Octagon Holes

Part: Fountain 30deg

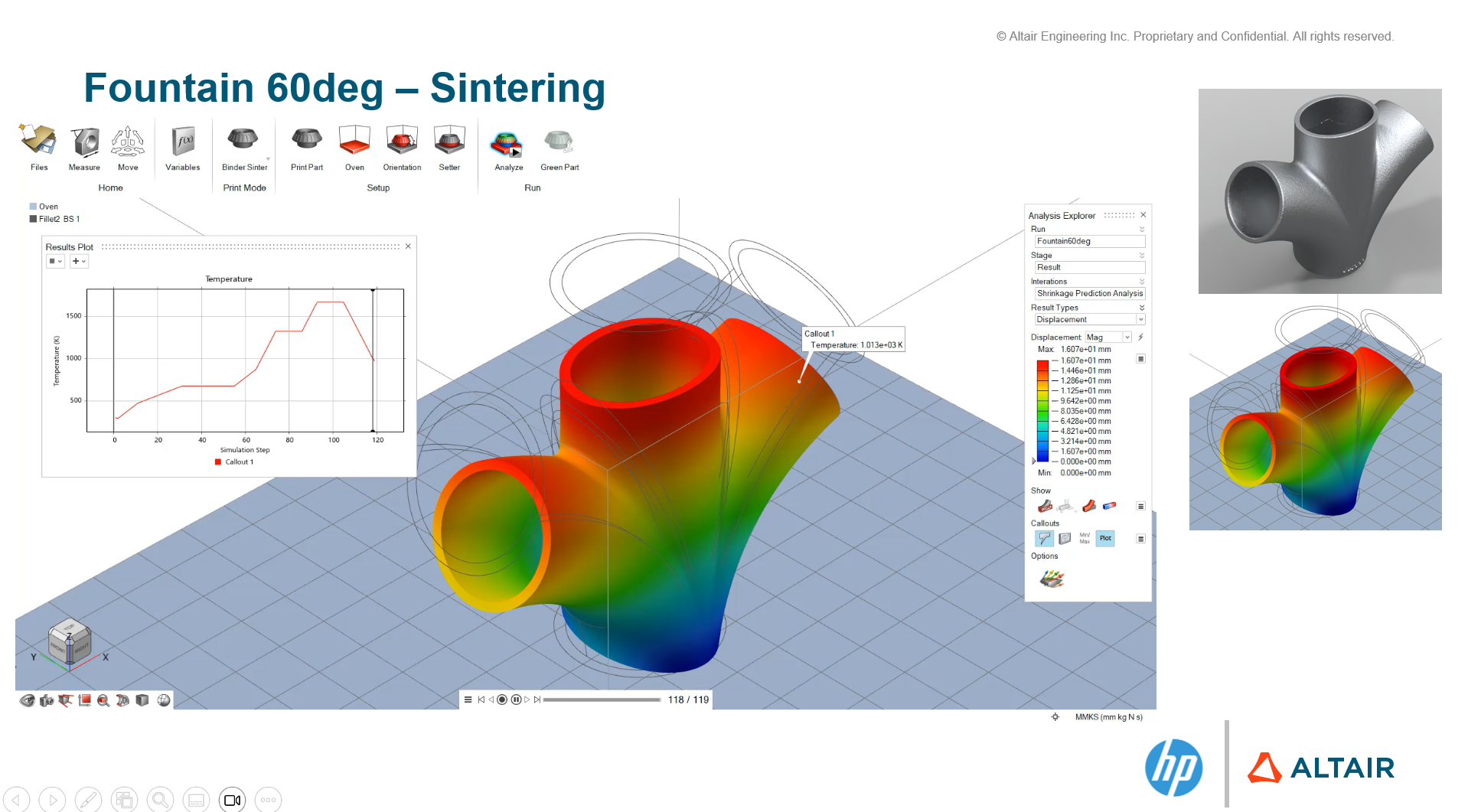

Part: Fountain 60 deg

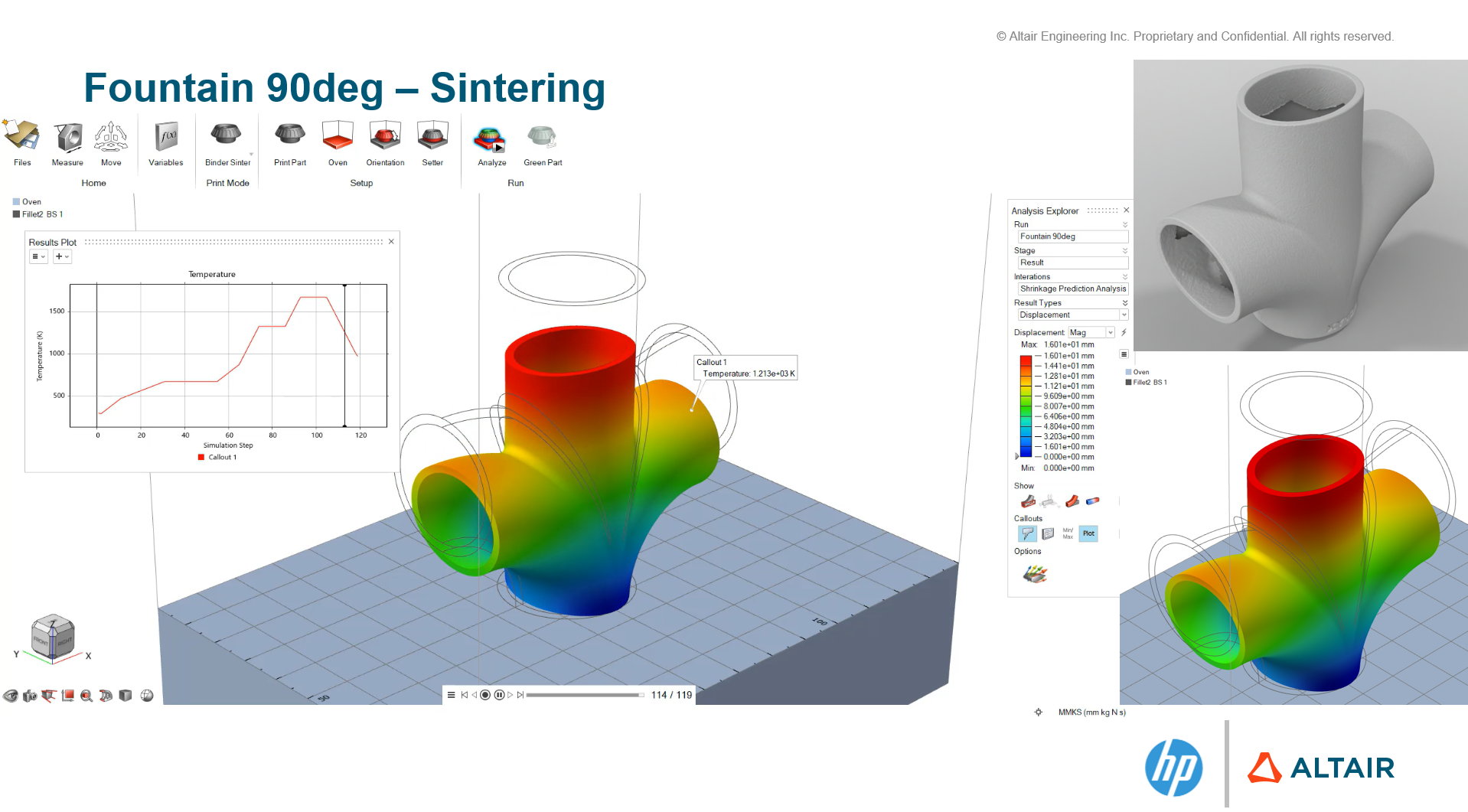

Fountain 90 Deg

Why do we need simulation?

Not all parts produced through sintering are identical. Variations arise due to:

- Inherent process inconsistencies

- Material property fluctuations

Simulation accuracy is constrained by:

- Assumptions made in the underlying models

- Simplifications necessary for computational efficiency

Bridging the gap between simulations, compensation strategies, and actionable outcomes remains a key area of focus. The continuous effort to align theoretical predictions with actual production results is crucial for advancing the reliability and effectiveness of sintering simulations in additive manufacturing.

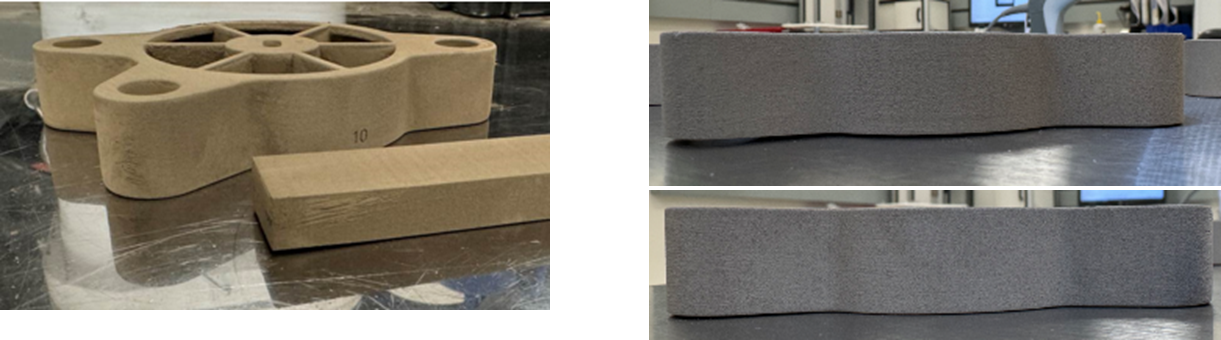

The case study shows a green part with a warped bottom surface. This warpage occurred due to the printing process. If ignored in simulation, stress concentration predictions will be wrong. It's crucial to consider all variables in the printed part for accurate predictions. This includes initial geometry deviations and surface irregularities. Accurate simulations lead to better part quality and production efficiency.

Summary:

Inspire Print addresses the growing need for sintering simulation in 3D printing, offering advantages like energy efficiency and complex part production. Inspire Print uses advanced constitutive models, including SOVS and Two-phase models, to predict material behavior during sintering. Collaboration with HP provided valuable part geometry and experimental results for validation and improvement. Shrinkage predictions match well with experimental data. Accurate simulations require consideration of all variables, including initial part geometry deviations, to bridge the gap between predictions and real-world outcomes.