Hi, everyone.

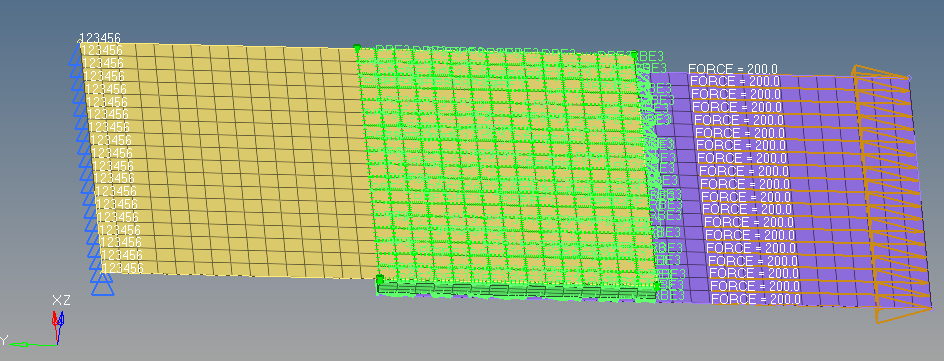

I created a simple model of two rectangular plates connected by adhesives between them. In this model, all degrees of freedom are constrained at one side , the distributed force is applied on the other side. The property of plates and adhesive are Steel and Epoxy Glue, respectively.

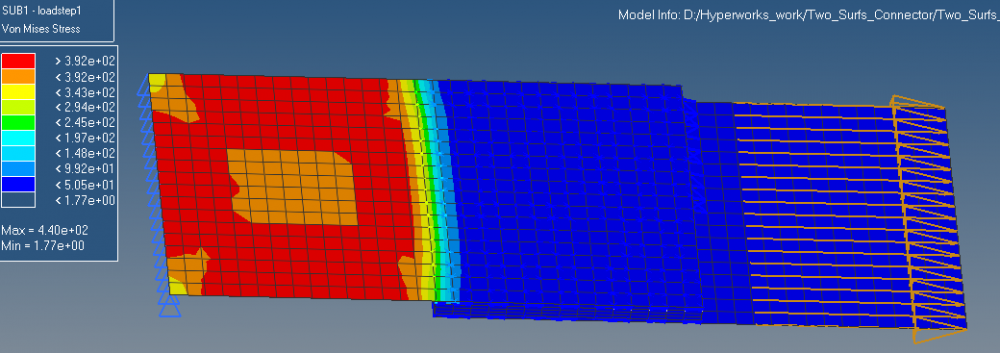

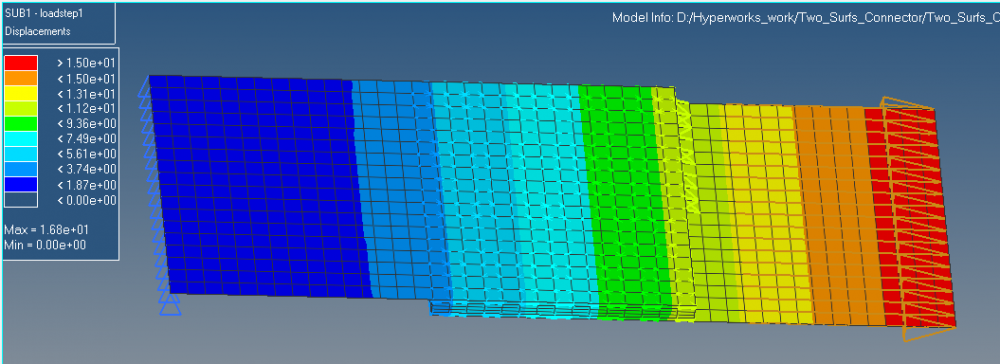

(1) Why are there great differences between the stress distributions on two plates? The stress level of the plate with constraints is much higher than the other plate, why? (Is induced by the clamped constraints?) I think there are also problems with stress concentration and displacement.

(2) Why is the stress level of adhesive so low?

Can anyone give me some advises?

Thanks.

<?xml version="1.0" encoding="UTF-8"?>

<?xml version="1.0" encoding="UTF-8"?>

<?xml version="1.0" encoding="UTF-8"?>

Unable to find an attachment - read this blog