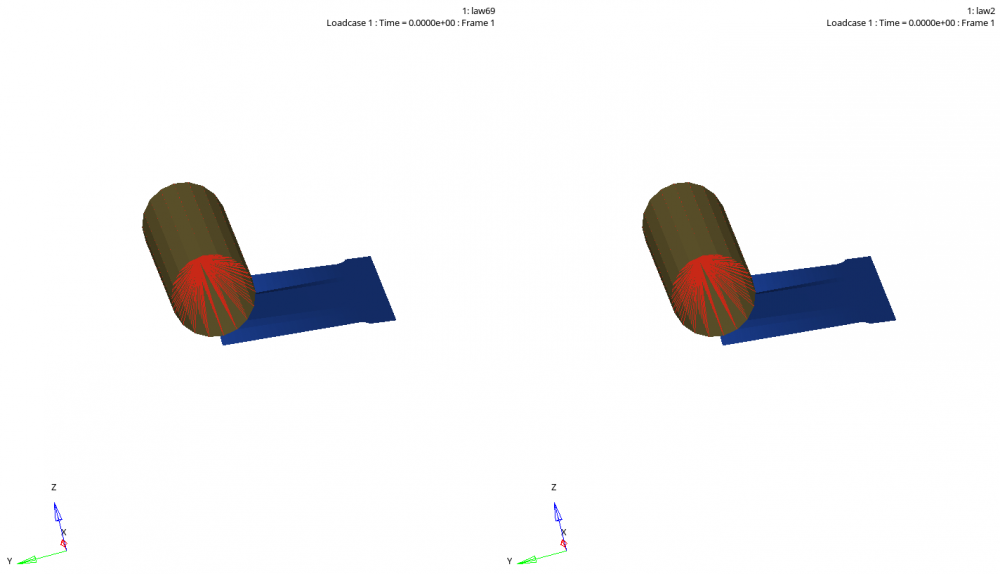

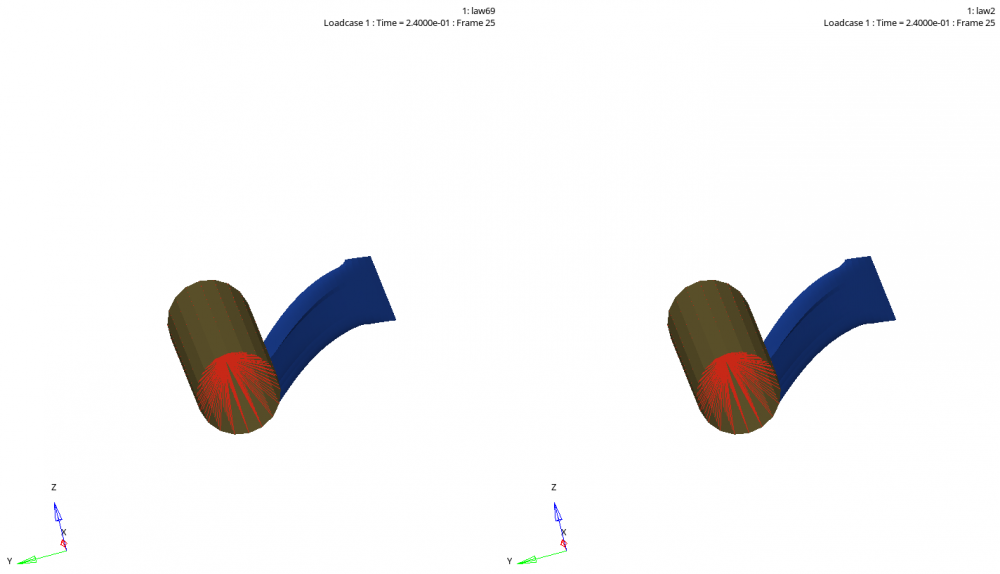

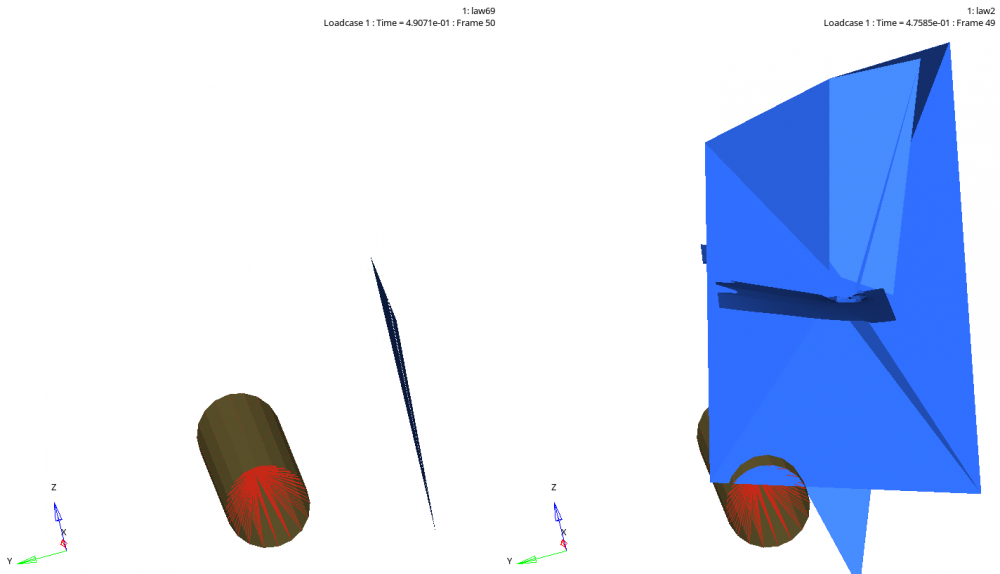

Hello, I am trying to model the correct bending stiffness and rebound and damping behavior of a rubber plate. My plate is meshed with 3mm shells adn 6mm P1 property. I tried with Mat Law2 and Law69 and in both cases my model 'explodes' on the rebound. See images below and both model files attached. Any help in figuring out what I'm doing wrong?

Thanks!

<?xml version="1.0" encoding="UTF-8"?>

<?xml version="1.0" encoding="UTF-8"?>

<?xml version="1.0" encoding="UTF-8"?>

Unable to find an attachment - read this blog