Hello everyone,

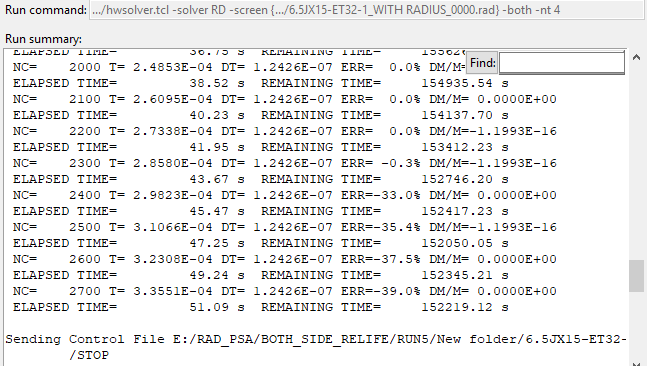

i am facing negative % ERROR in radioss, due to % error convergence issue is occurring.

for reference i am attaching the .out file.

pls let me know how can i resolve the issue.

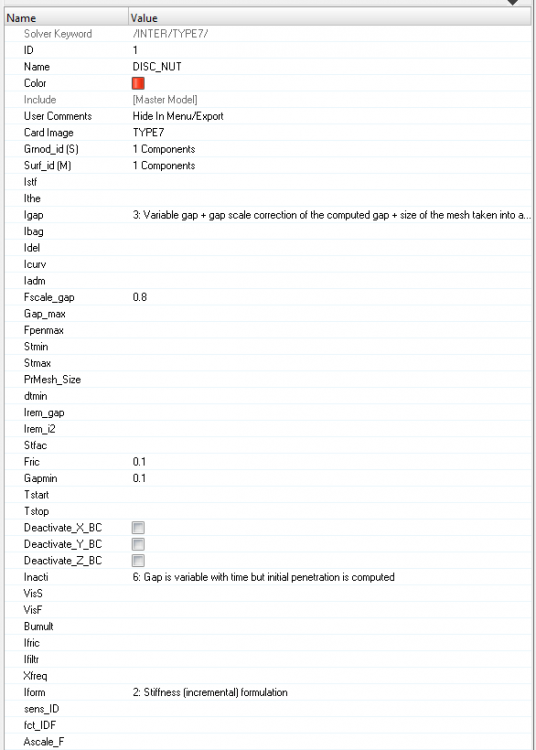

One thing i want add is this % error is occurring when ever i am using contact between master and slave component,

i am sure there is no any penetration between slave and master.if i am simulating the problem without any contact , like directly applying load on component node,

there is no issue occurring.for reference i am also attaching the snap shoot of contact assignment.

<?xml version="1.0" encoding="UTF-8"?>

<?xml version="1.0" encoding="UTF-8"?>

regards

Unable to find an attachment - read this blog