Curious about your vehicle model's ability to meet Double Lane Change Standards? This video demonstrates the effective utilization of MotionView sensors to fulfill this requirement! The integration of sensors for the Double Lane Change maneuver not only optimizes time during iterative processes but also enhances comprehension of your MotionView vehicle model's constraints. The tutorial encompasses various aspects: from the double lane change segments, importing and affixing the sensor system to a MotionView vehicle model, modifying section parameters, post-processing MotionSolve results, and expanding sensor integration for multi-axle vehicles.

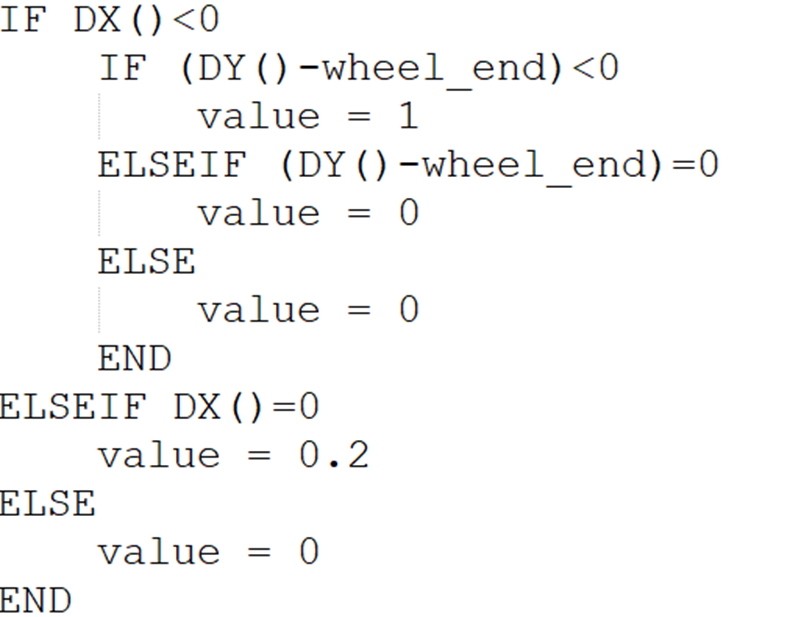

IF(DX({arg_cone.r.idstring},{arg_wheel.r.cm.idstring}):

IF(DY({arg_cone.r.idstring},{arg_wheel.r.cm.idstring})-{arg_wheel_end.value.lin}:1,0,0),0.2,0)

An easier representation of the syntax.

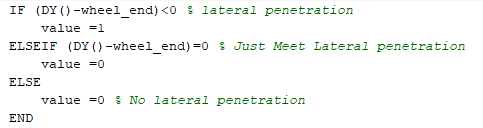

Referring to Sensor Section 1 Right Tire.

Assuming that DY is not triggered. If the value reported by DX is 0, the value recorded by the IF statement will be 0.2. If you are referring to the Sensor Plot, 1 will be returned. Think of it as a binary switch, 0 will be returned since the sensor hasn't been triggered. A value of 1 will be returned if the sensor is triggered.

This is how it is being for the right tire interpreted (All due to how DY was formulated in the expressions).

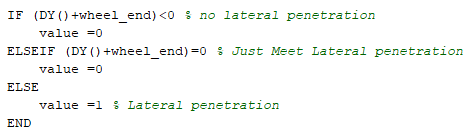

For the Left Tire, this is how it is being interpreted.

Regarding the DX statement, the sensors will only trigger if the DX value of the wheel and cone is exactly 0. If the value is non zero for EXPR 4, that would trigger the sensor. Then the simulation will halt every time after the vehicle crosses over the first section.

To account for this, DY of the wheel ends and the cones were also included. If the vehicle penetrates the wall in the X direction, the vehicle is not within the bounds of the next section in the Y direction, which would cause a sensor to trigger regardless.