Hi all,

I have a question about using contact ties to attached weld elements to a structure.

In a nutshell,

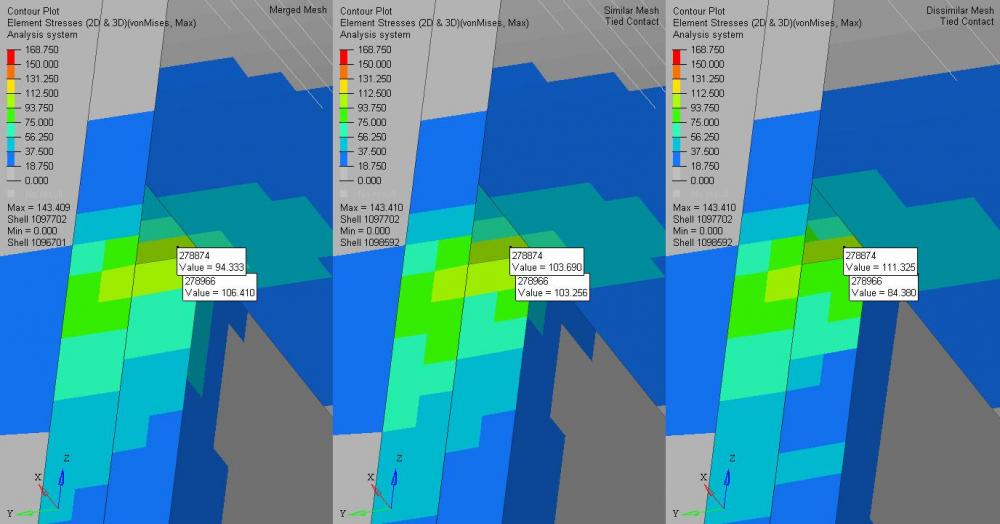

I've been asked to bring 2 models together with a dissimilar mesh and weld them. In the attached image on the left is a typical merged node to node approach with no contact - this would be our traditional approach. The middle contour plot is the same model but the weld is detached from the structure and is connected via a tied contact. The right contour plot is with a dissimilar mesh (similar to what I have been tasked with) and using the same contact tie set up as the middle contour.

As you can see there is some variation between all three contour plots. Ideally I want to be able to use the approach in the right plot as this would cut out significant amounts of remeshing. However I do need to justify this approach.

1. Why is there such a difference between plot results?

2. Has this approach been used by others and if so why?

3. Is the contact tie approach acceptable for this application?

4. Are there any published references which can be used to support this approach?

Any help is always appreciated, I don't always get a notification when people reply so apologies if there is a delay.

Kindest regards

Andy

<?xml version="1.0" encoding="UTF-8"?>