- RESEARCHER

- Dr Sadegh Nadimi

- INSTITUTE

- University of Leeds, UK

- DEPARTMENT

- Faculty of Engineering

- SUPERVISOR

- Prof Mojtaba Ghadiri

- TIMELINE

- 01/01/2018 - Ongoing

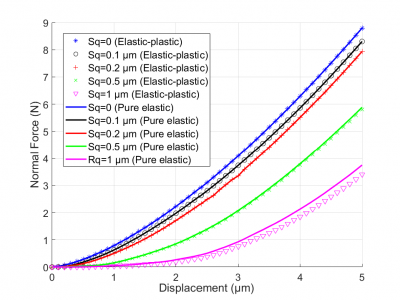

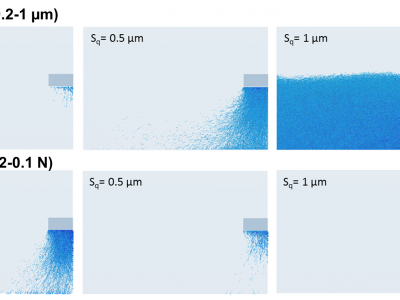

In shear flow of powders and grains, particles slide and roll over each other. Consequently, their tribological properties such as friction and adhesion play a major role in their flow behavior. Particle surface roughness strongly influences bulk material flow through its effect on adhesion and friction. In this work, Boundary Element Method (BEM) is coupled with DEM to predict the bulk behavior of particulate solids more accurately. An in-house BEM code is employed to calculate the normal force-displacement curves. This is an efficient and relatively fast method to calculate the contact mechanics of rough surfaces. The realistic contact behavior is then implemented in DEM to determine the effect of micro-scale surface roughness on angle of repose and bulk compression of granular materials. This study highlights the effect of surface characteristics on contact behavior of particles and provides an efficient approach for modelling of large number of rough particles.

Fig 1. Normal force vs displacement for a contact of rough particles

Fig 2. Compressive forces in rough particles beneath the footing

Fig 3. Normal contact deformation and force network for particles with different surface roughness

EDEM is very flexible software. The built-in API and coupling interfaces help users to develop a more realistic simulation.