- RESEARCHER

- Emerson Reikdal Da Cunha

- INSTITUTE

- Universidade Federal Do Rio De Janeiro, Brazil

- DEPARTMENT

- Metallurgical and Materials Department

- SUPERVISOR

- Rodrigo Magalhaes De Carvalho

- TIMELINE

- 2016-2017

Given the limited control that exists in the sizes of pellets that leave pelletizing drums or discs during balling, size classification by screening becomes of central importance. The work analyzes the performance of the main type of screen used in classification of green iron ore pellets, the roller screen, through simulations using EDEM software. Recognition of the sticky nature of the material led to the choice of the Hertz-Mindlin model with JKR cohesion (included in EDEM) to describe the contacts. The simulations using EDEM were used to analyze the sensitivity of the roller screen performance to selected material and operating variables. SPONSOR Capes, Faperj

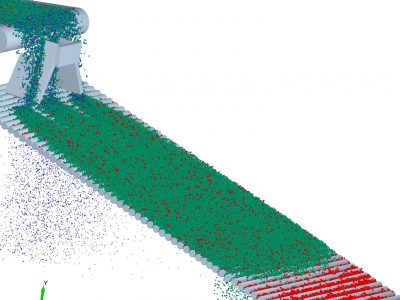

Fig 1. Single deck roller screen

Fig 2. Green iron ore pellets represented using EDEM

EDEM allowed the detailed description of the classification phenomena that occurs in roller screens used on pelletizing plant. The contact model coupled with JKR cohesion model were calibrated and resulted in observations close to industry experience regarding return rate, fines removal and other process parameters.