The summer of 2007 when I was 18 years old was hands down the best summer of my life. Why? Because my best friend got her driver’s license and with that, access to her mom’s car. We grew up in a very small town and the only way to get around was by bike or bus. But that summer everything changed, because now we had a car!

Expectations were low in terms of comfort, to the point where I could feel every bump on the dirt roads. Noises such as squeaks and rattles would emerge from the cockpit, doors, and seats. Being young we were more than willing to put up with this as long as this car could still take us on adventures, especially to our favorite place: Smygehuk, the southernmost point in Sweden. We would park in front of the ocean, roll back the seats, plug in a CD, watch the waves, and eat juicy Swedish strawberries. Close your eyes and picture it. Idyllic right? Well not so much when your favorite songs (and yes, the volume might have been a little too high) is ruined due to the rattling and buzzing of the car trims and speakers!

More than a decade later, the automotive and audio industries have made tremendous progress. Advanced testing of speakers in various environments have improved the final product quality. Not only for brand new products, but also after years of usage.

While physical testing is a well established practice, virtual testing is the latest, most reliable advancement. At Altair, we have a simulation tool and process called Squeak and Rattle Director coupled with Altair OptiStruct™, the industry-leading solver for structural design and optimization. Using this process, one can evaluate the acoustic performance of any product. In the case of a loudspeaker, the sound distribution in the car or a room can be simulated. Furthermore, anomalies or annoying noises such as squeak, rattle and buzz can be identified before the product is physically built.

https://www.youtube.com/watch?v=P2jn6rcGJKI

https://www.youtube.com/watch?v=P2jn6rcGJKI

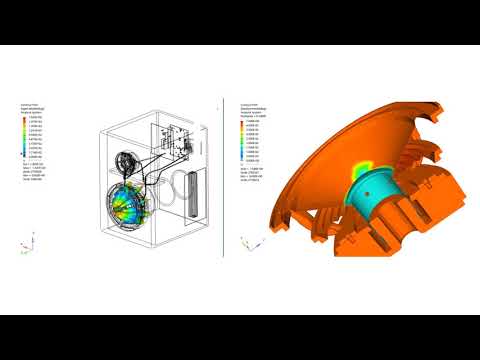

Using a finite element analysis (FEA) approach, the loudspeaker system vibration can be reproduced, as shown in animation above. The vibration induced and transferred to the rest of the structure can be measured, diagnosed, and optimized if required.

The analyst can visualize the sound pressure level (SPL) distribution in a room for example, shown in figure above. Virtual microphones are placed at every desired location, and the sound pressure level can be plotted versus frequency.

But the additional advantage of virtual testing is the detailed interrogation of the design. Being able to measure locations that are usually not accessible in a product, for example, inside a speaker. Or measure a scenario almost impossible to reproduce. For example, the rattle noise between parts of a speaker will only occur when the system is in operation. The problem is that a speaker will emit sound which will interfere with the undesired noise your try to detect, diagnose, and eliminate.

Using simulation, one can measure the sound pressure level for variable scenarios:

This streamlined simulation process allows engineers to identify any hidden issues in very complex systems such as speakers or cars. When detected, the problem can be engineered and solved before any prototyping or physical testing is conducted, reducing very high warranty and corrective maintenance costs.

Now, 13 years later, I am working in the field of simulation-driven design, noise and vibration, and perceived quality, helping some of the largest automotive and consumer electronics OEMs (Original Equipment Manufacturer) around the globe design better products. By doing so, I hope to innovate but also bring joy to many people out there making sure they can fully enjoy idyllic moments in their cars or homes for all summers ahead!

Intrigued and want to learn more? Don't miss our Consumer Electronics Webinar Series in which this topic is covered more in detail or just message me and we'll set up a call!

Stay Safe and make sure to treat yourself to some nice tunes and delicious strawberries!