- RESEARCHER

- Subhodh Karkala

- INSTITUTE

- Rutgers University, USA

- DEPARTMENT

- Chemical and Biochemical Engineering

- SUPERVISOR

- Rohit Ramachandran

- TIMELINE

- Ongoing

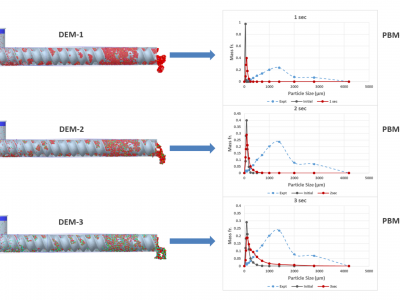

The simulation of granulation process in a twin screw granulator (TSG) was achieved by bi-directional coupling of a discrete element method (DEM) model and a population balance model (PBM). EDEM was used to build the DEM model for the TSG and simulate particle flow inside it. The DEM model was divided into different zones based on the screw elements of the granulator and particle-scale data from each of these zones were provided to the PBM. The PBM then uses this information to predict the particle size changes in the granulator after a short period of time. The PBM provides the updated size distributions and particle densities back to the DEM model to complete the bi-directional coupling and start a new coupled simulation. The coupled model is run several times using the updated parameters from the previous PBM. Once steady state is reached, the final particle size distribution calculated by the PBM will be compared to the experimental results for validation. SPONSOR: BASF

Figure 1 - DEM model of the Twin Screw Granulator

Figure 2 - Coupled simulation results from the first three DEM and PBM runs

EDEM has a user-friendly interface and DEM models can be setup very easily. The post-processing tools are also very powerful.