- RESEARCHER

- Luu Duy Nghia

- INSTITUTE

- Nanyang Technological University, Singapore

- DEPARTMENT

- Mechanical and Aerospace Engineering

- SUPERVISOR

- Zhou Wei

- TIMELINE

- Jan 2019 - Nov 2019

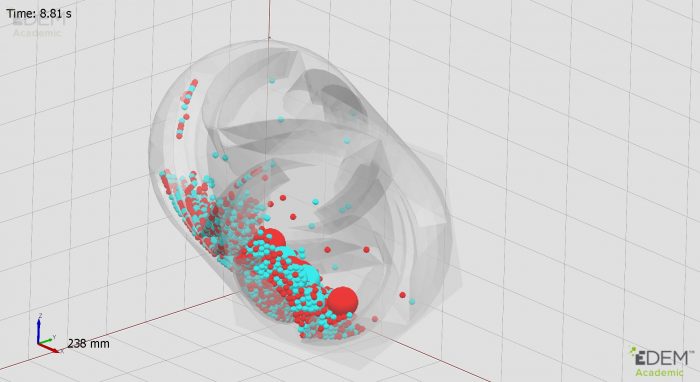

Simulation of powder mixing process, that was based on the movements of a tumbler mixer, was carried out. An experimental design of the powder container was used, and its performance was compared to another container with no additional design. Both containers were subjected to the same simulation conditions. The aim of the experimental design was to replace the use of spherical balls in the mixing process. The reason for the use of the spherical ball were to increase the forces on the powder. As such, the number of contacts among the powder particles and the forces exerted on them were measured using the EDEM software. Simulation results showed that by increasing the number of balls by 2 times, the average normal forces exerted were increased from ~0.0195N to ~0.0350N and from ~0.0140N to ~0.0180N when the experimental design was and was not applied respectively. This suggests that the addition of the experimental design is effective in increasing the amount of forces exerted on the powder particles. Simulation results also showed that the homogeneity of the powder mixture was not compromised at the end of the simulation when the experimental design was added. The video below shows the movement of the container with the experimental design from 4 different angles. The video runs at half the original speed. The rotation of the container is designed to be 30 rpm. The radii of the powder particles and the bigger balls are 1.31 mm and 6.56 mm respectively. Both have the same solid density of 8.19 g/cm3. The particles are divided into 2 different colors with equal amount of mass for ease of identifying the mixing homogeneity. The images entitled Figure 2 and Figure 3 show a close up view of the design inside the container.

video

Figure 2.

EDEM software was easy to use and user friendly. Within a short period, I was able to quickly learn and make use of the software with the aid of the incredibly helpful customer support service and their online eLearning platform. The software enabled me to test the feasibility of my idea without having to make a physical prototype.