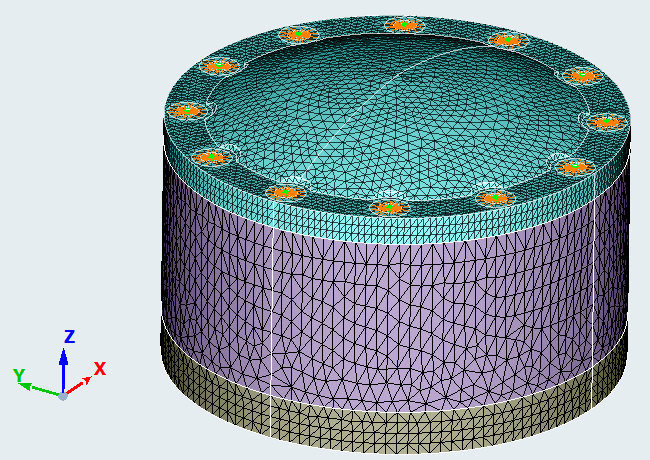

For practice with bolted assemblies, a simple three-body STEP assembly was created for a Dome Pressure Box.

The base and cylinder are separate bodies. These can be Boolean or Join together for learning sake. Try the Boolean and learn to connect them as a single body with two volumes, and what that implies. Or Join the surface meshes and Remesh the interface, until a nice transition mesh is achieved. You may need to play with Mesh Controls on faces or edges for good transition.

The domed body will be connected to the cylinder by 12 bolts. Your choice how to create.

- Manually create the flat spiders to washer faces (you create!), upward facing spiders near bottom of holes, and Bar elements connecting the spiders.

- Bolt Head creation, to automate creating the bolt head flat spider to washer face, and Bar element to the interface plane.

- Bolt Thread creation, to automate same for upward facing RBE2 and Bar element. I never succeeded getting this working, so quite easily created manually.

- Automated Bolt Head creation based on search of hole of size range, like the Altair demos, and same for Bolt Thread.

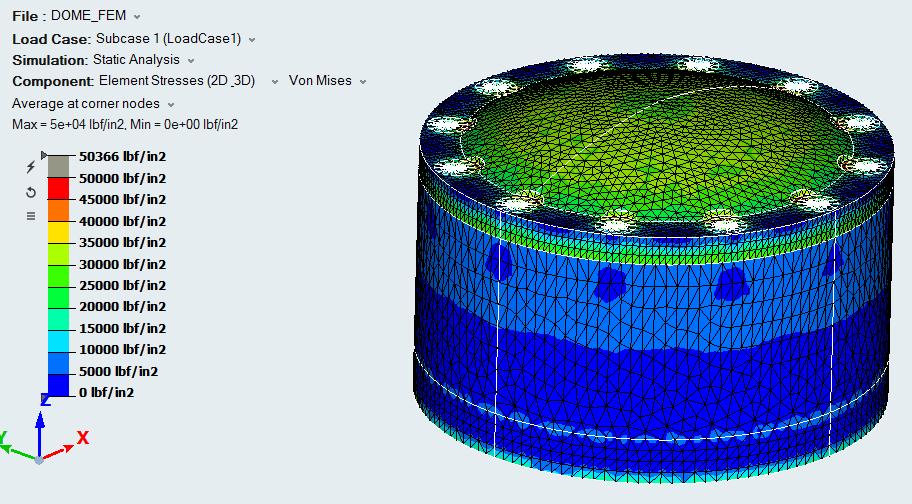

Let me know if anyone gets the Bolt Thread feature to work, and how-to-do. I tried hard, and always failed with nothing displayed after the pop-up it had succeeded. The intention is to apply a 1500 psi internal pressure loading, e.g. a exploding device within, and compare stress contours in psi vis Simlab 2019.3. Bolts are 0.25'

The solid assembly was quickly crafted in NX-IDEAS 6.1, with its superb and easy yet powerful modeler, but Windows updates may finally kill the great product. Darryl

<?xml version="1.0" encoding="UTF-8"?>

<?xml version="1.0" encoding="UTF-8"?>

Unable to find an attachment - read this blog