I'm currently working on a unit cell study (carbon fiber + matrix + additives). I thought it would be very easy to mesh it out and run my test, but I've been spending too much time in determining good quality of mesh. I have 3 components (3 different solids) that need to be meshed.

I was able to successfully tetra-mesh individual solids with curvature and proximity, but couldn't find the way to somehow connect them.

I tried to re-mesh multiple times with 2D automesh to tetra mesh technique, translating surface meshes to another, assigning equivelent on the duplicated nodes, etc. But frankly, it's too time consuming to accomplish good quality mesh, and I can't spend more time in this part.

Later on I found the contact surface method preventing the penetration between parts by assigning slave and master BCs on shared surfaces (i.e. outter surface of carbon fiber and inner surface of matrix). Please give me some advice whether node connectivity can be replaced by assigning contact surface. My one concern is that later on I'll have to check the carbon fiber penetration in a reality scenario, and this method won't work for that due to the slave/matster bounded condition. If node connectivity must be properly done (which I assume..), please provide me some type of tutorials that present about connecting 'multiple solids'. I've went thru lot of meshing tutorials but only found the ones for single component/part or simple geometry setup that can be easily automeshed/translated/rotated..

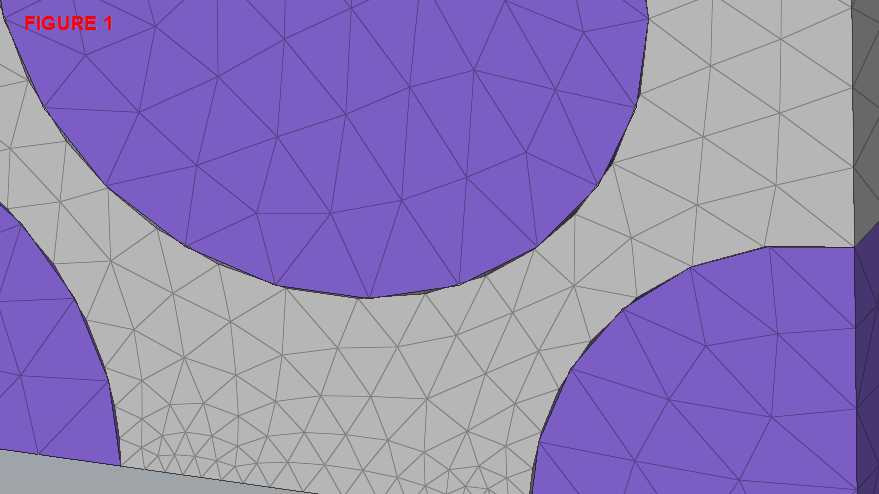

Figure displays the carbon fiber (purple) and matrix (gray) nodes are not connected.

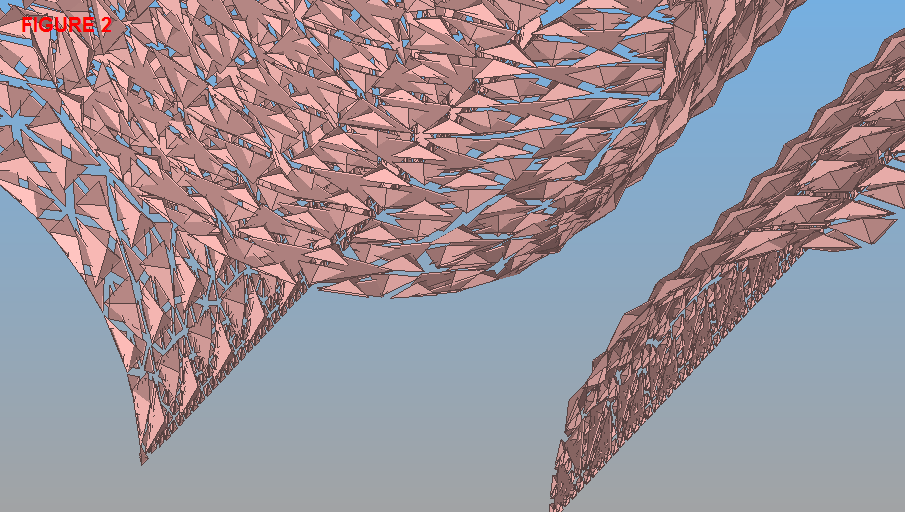

Figure 2 displays the contact surface BCs applied on the shared surfaces of carbon fiber and matrix.

Please excuse that I am not allowed to upload the model..

Your help would be really appreciated.