Hi,

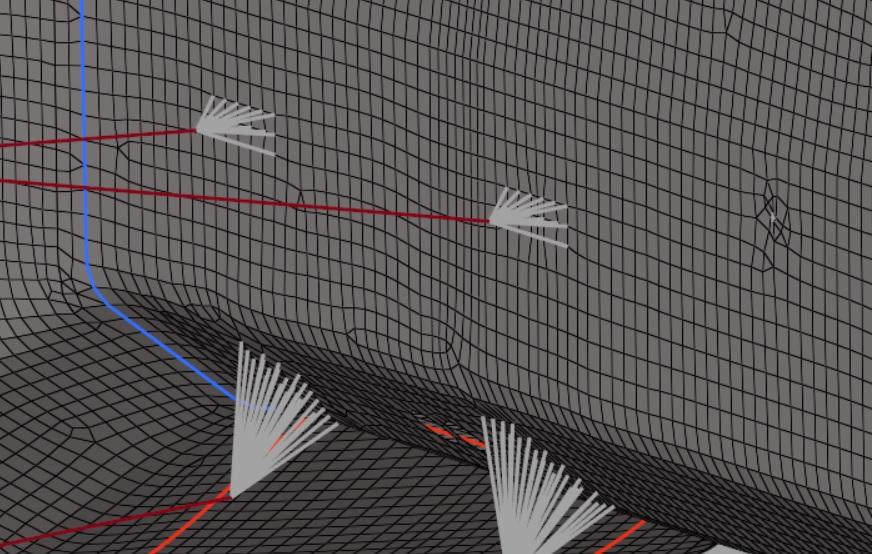

I need your opinion and experience to solve a problem. I’m making a composite optimization on a monocoque, and I’m having some problems modeling the suspension. We have some supports that make the connection between the A-arms of the suspension and the monocoque (I’ll attach one photo). We have problems because we simulate the support with a RBE2 (independent node on the A-arm, dependent nodes in the monocoque; I’ll attach one print-screen), and this gives infinite stiffness on the laminate, so in the results of the optimizations there are almost zero stresses on the elements that have nodes on the rigid. This affects our optimization a lot, so the area off the supports are one of the most weak points on our stucture (some of them even started to break on our last monocoque). We even thought about using RBE3, because it doesn’t give additional stiffness, but the way that it works seems to not make sense in our case. What do you suggest to do in order to simulate this in a more proximity to what really happens?

Thank you

<?xml version="1.0" encoding="UTF-8"?>

<?xml version="1.0" encoding="UTF-8"?>