Hello,

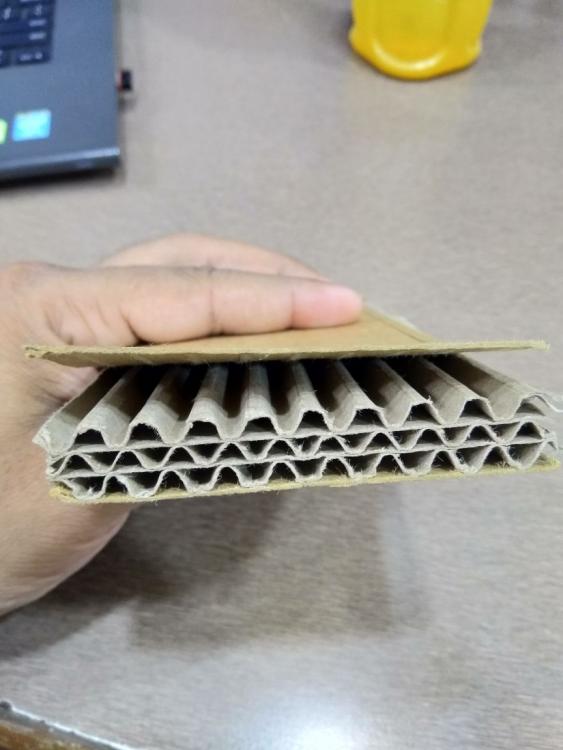

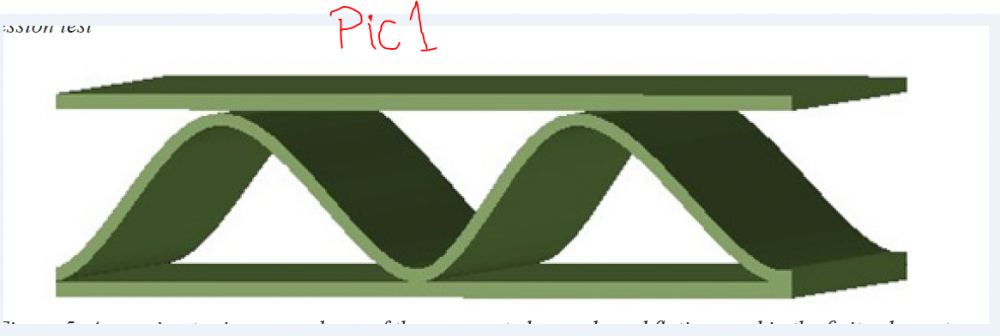

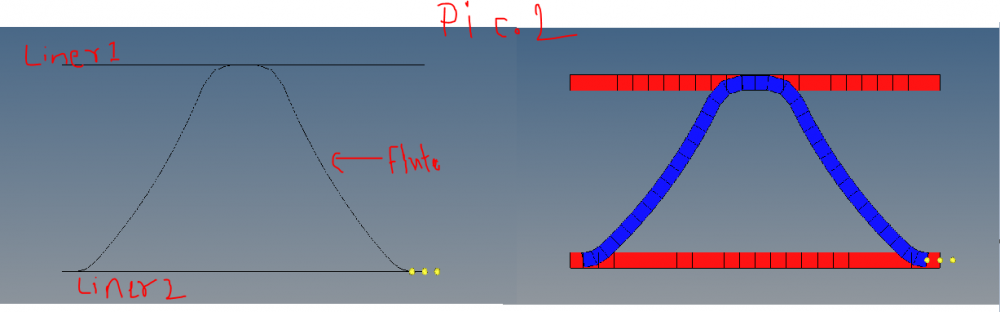

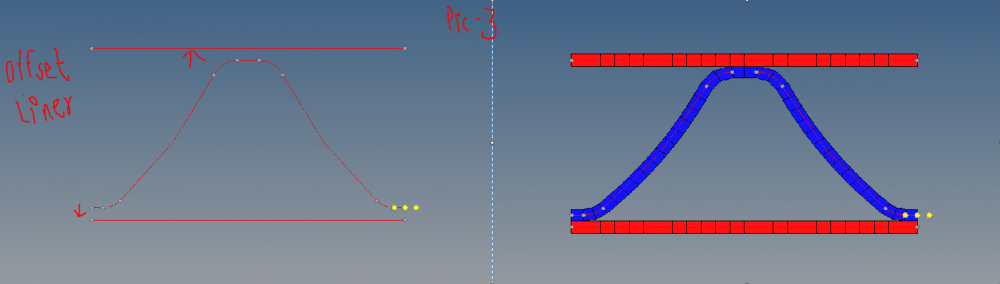

I am doing analysis for Corrugated fiber board box i.e CFB box. Its Structure is as per Pic1. So I took mid surface of it, and shell meshed it.( Refer Pic2). In same case, I simply offset both the liner, and then meshed it. ( Refer Pic3) Now, which one is correct and give better result without any issue?

1. In 1st case is there any issue regarding initial penetration? liner and flute have different properties and material.

2. Do I need to give contact interference in any case?

3. In actual scenario, there is adhesive between Liner and flute to stick together.(Pic4). Do i need to use connectors?

4. Suggest any other appropriate technique....

<?xml version="1.0" encoding="UTF-8"?>

<?xml version="1.0" encoding="UTF-8"?>

<?xml version="1.0" encoding="UTF-8"?>

<?xml version="1.0" encoding="UTF-8"?>