Hi,

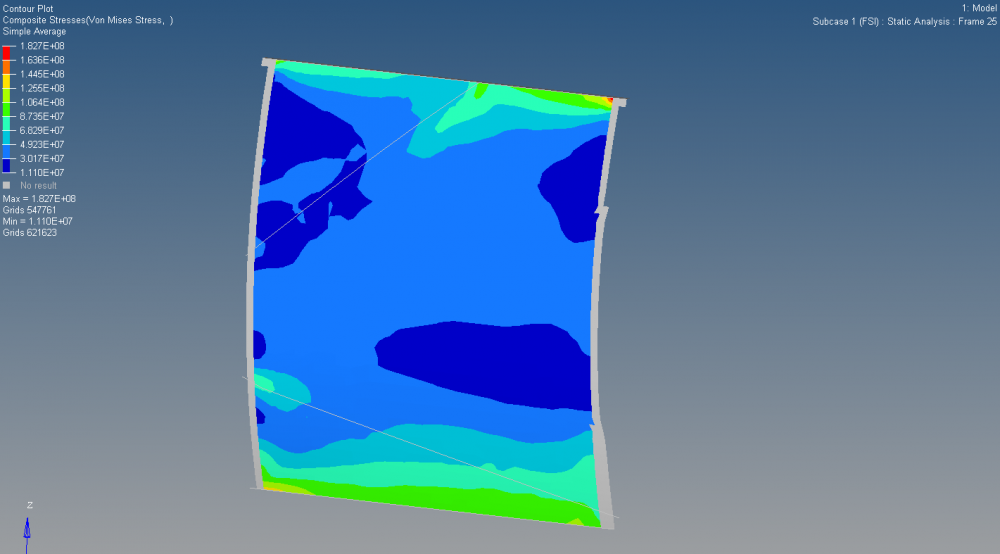

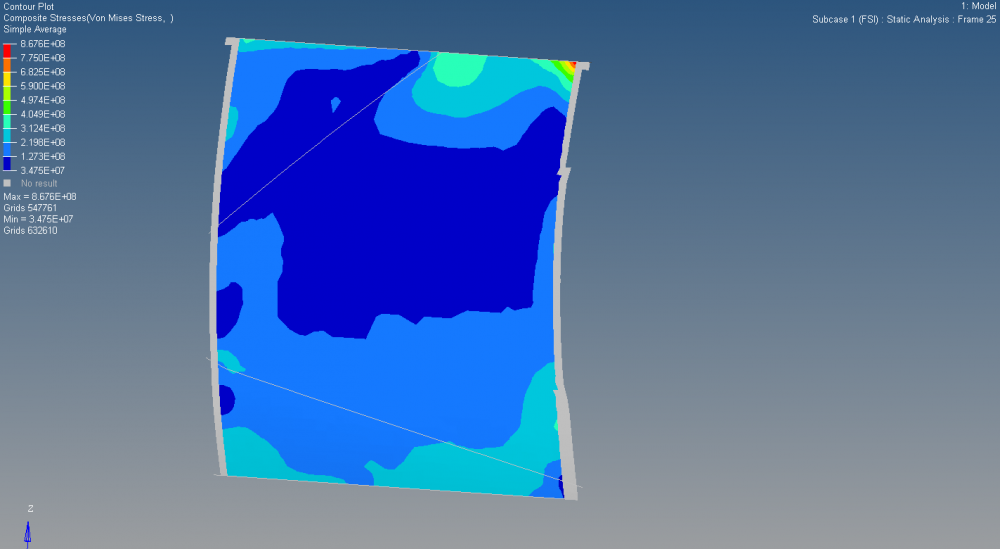

I am modelling sandwich panels applied to a wall with loading in various cases. In sandwich theory, the stress should decrease with core thickness. However when the core is thick here, the minimum principal stress is much higher than when the core is thin.

I am aware there is a high load specifically at this point in specific so stress is high, however stress should still decrease with increased thickness. I am wondering if anyone has an explanation to help me understand?

Thin Composite:

<?xml version="1.0" encoding="UTF-8"?>

![]()

Thick Composite:

<?xml version="1.0" encoding="UTF-8"?>

Unable to find an attachment - read this blog