Hello everyone,

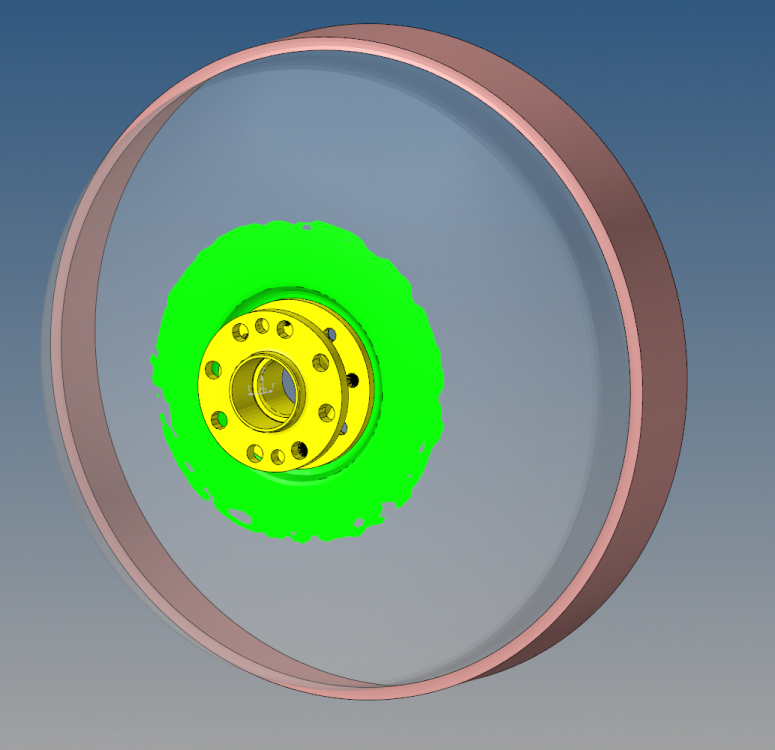

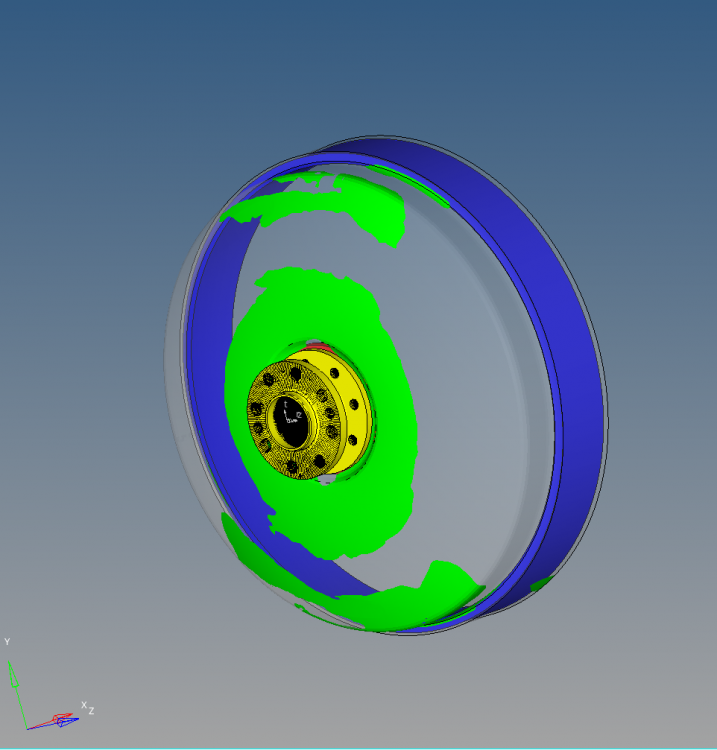

I have a rotor cover submodel where i'm doing a topology optimization of the cover to see where I can remove some elements to lower the mass. I tried running a static analysis with a centrifugal load(RFORCE) and one with an applied moment force but I didn't get any plausible results. You will find a picture with the result attached(green is cover, blue magnets tied to the cover).

I would like to know if the approach is correct or if I should try something else. How is one to approach optimizing models involving rotation (centrifugal load , moment)?

Thank you in advance!

<?xml version="1.0" encoding="UTF-8"?>

<?xml version="1.0" encoding="UTF-8"?>