Hi, a bit of a broad question here but I thought I'd ask one long one rather than many short ones when I inevitably get stuck at the next step!

I'm a university student that's new to HyperWorks. I’ve never had any training nor does anyone else at my university know how to use it but I do have access to all the tutorials, however they are obviously simpler than what I’m trying to do so any help would be very much appreciated.

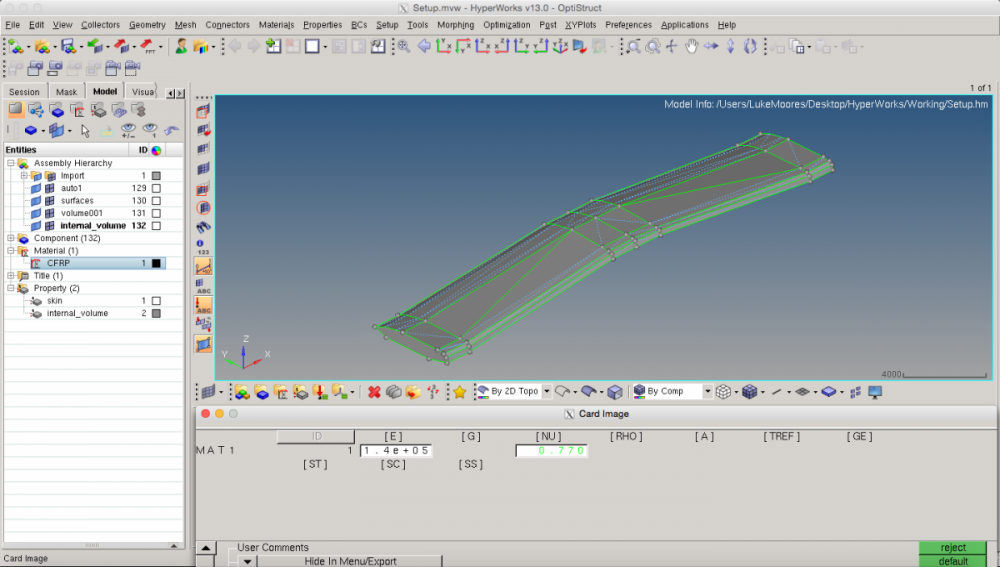

I want to conduct a topology optimisation on the central wing of a twin fuselage aircraft with the skin being non design space and the entire internal volume being design space.

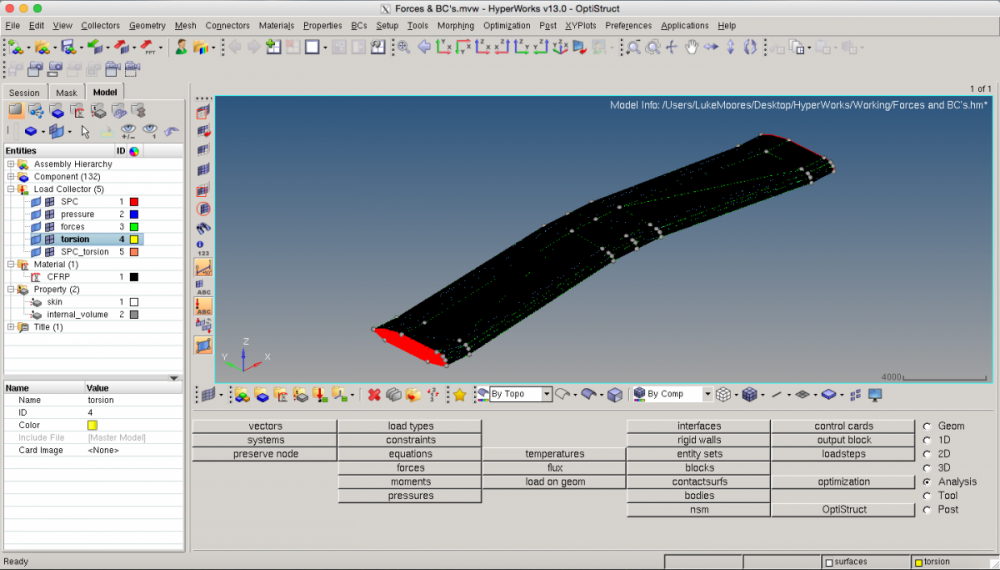

I'd like to run the optimisation three times, for three separate load cases so that I can get three different internal layouts.

I've imported a hollow CAD model, 2D meshed it's surfaces, 3D meshed it's volume and set the boundary conditions for all the nodes on both ends. I've also made collectors for the three different loads, two different boundary conditions (for the torsion load only one end will be fixed) as well as for the properties of carbon fibre reinforced plastic. I'm planning on using the load collectors to make the three different load cases and then use loadsteps to separate the three cases.

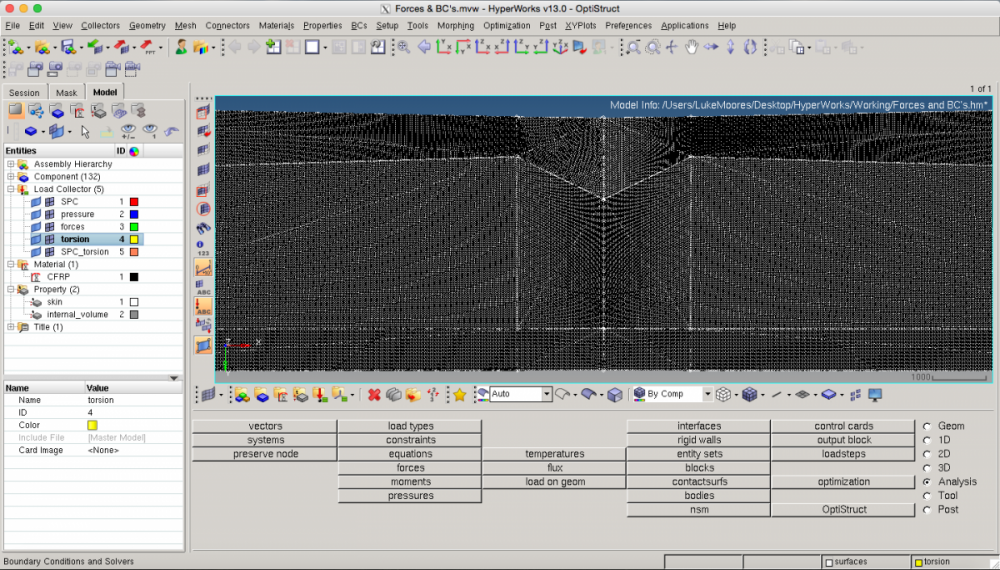

The part I'm stuck at is how to approach setting the loads. For the pressure load I want to apply six different patches of uniform pressure along the upper and lower surfaces of the wing's chord to simulate the pressure distribution around it. I then want to set a force with a vertical and horizontal component to represent the weight and drag of the payload it's carrying (the aircraft is Virgin Galactic's White Knight Two). Finally I want to apply a moment about one of the ends whilst the other is fixed in order to simulate a difference in pitching moments between the two fuselages. A particular problem I'm having is how to apply the force and moments to entire surfaces rather than individual nodes, as in rather than applying a certain load to individual nodes I want to distribute the force / moment over all the nodes on that surface.

I've already spent hours trying to teach HyperWorks to myself but any advice you could give me or any resources you could point be towards would be hugely helpful! I've attached a number of screenshots to try and show you what I'm trying to do.

Thanks for taking the time to read this,

Luke

<?xml version="1.0" encoding="UTF-8"?>

<?xml version="1.0" encoding="UTF-8"?>

<?xml version="1.0" encoding="UTF-8"?>

<?xml version="1.0" encoding="UTF-8"?>