Hi,

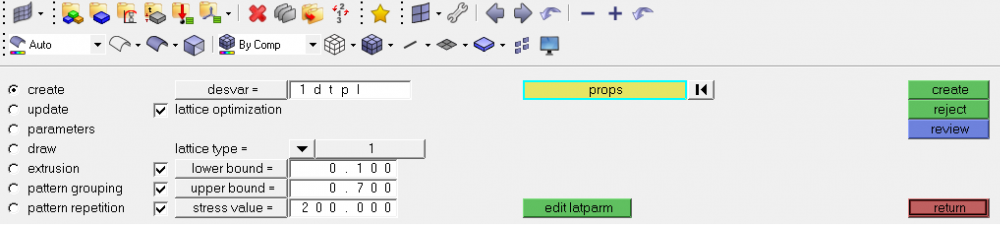

I just tried to use optisruct to do the lattice structure optimization. The lattice fem file was created but I am not able to see the lattice parts in the model. Could you please take a look at my file to see if I did it correctly or not and what is the problem. I used the lattice option in topology panel(I have attached the photo of it).

<?xml version="1.0" encoding="UTF-8"?>

Unable to find an attachment - read this blog