@Prakash Pagadala

Hello Prakash,

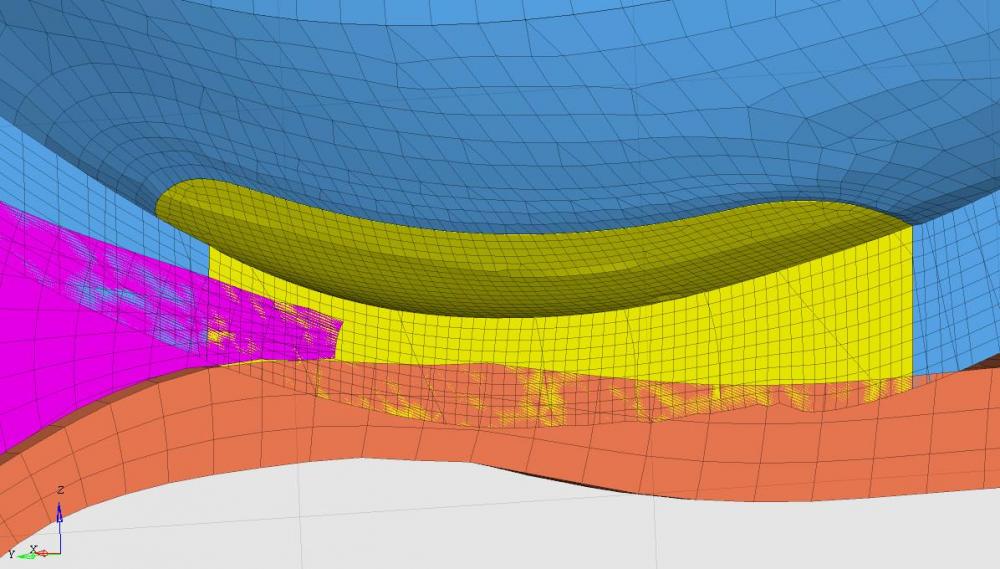

I am trying to simulate a model with several contacts in Optistruct (Non linear quasi static). The Materials are all linear but with very Little Young Module (40-300Mpa). But there are big Penetrations between sliding parts and the results are not correct.

Contacts with Problem:

ID 16

ID 17

ID 26

ID 27

ID 28

<?xml version="1.0" encoding="UTF-8"?>

I have followed all Solutions in this Forum but it did not work out. I have tried following Solutions:

-Contact type: SLIDE

-Nlparam NINC increase to 200

-CNTSTB load collector and CNSTB Card in Param (EXPERTNL)

- MORIENT= Opengap

-Additional Clearance: 0.1

-String Value>>Adjust>> Auto

-S2S and N2S (Both tried)

-Track INFINIT and Consli (Both tried)

- Symmetric Contact for IP 16 (2 identical contacts with reverse Slave/Master Component)

- PCONT>>STIFF>>HARD

Because the Simulation takes so much time i share the H3D results too.

Thank you so much for your help

P.s: I should mention that this Model with this Material Parameter has been simulated successfully in Abaqus.