Hi,

I'm currently experimenting with different connection types to simulate adhesive bonds. I want to find the best way to analyze large scale bonded shell models. So far I've been examined different options for area connectors, such as: shell gap, mid thickness, etc.

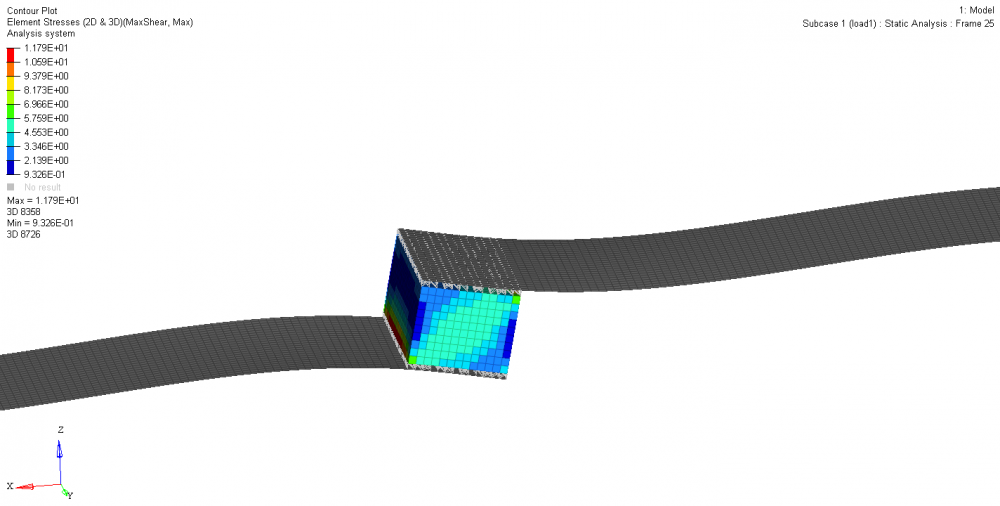

The problem I have is that when I increase the adhesive thickness I get some incorrect results. Up to 3 mm in thickness, all the results seem acceptable, but with 5 mm and 10 mm thickness it looks false. More details:

- I use Optistruct, and running a Linear Static analysis

- The adhesive layer seems too rigid, although I use the real parameters of the glue. It seems like the glue is trying to maintain its position (perpendicular) to the sheet, and isn't deforming enough.

<?xml version="1.0" encoding="UTF-8"?>

My question is: is there any rule regarding the range that a connector type can be used in? (For example: area connector in shell gap mode is good for adhesive layers in the 1-3 mm range.) Or in other words, is there a limit thickness where adhesive area connectors can't be used anymore?

I attached the model I was using.

Also, what modelling method can you suggest to analyse large scale shell models with adhesives (for example: a boat)?

Thanks,

Sebo

Unable to find an attachment - read this blog