Good morning,

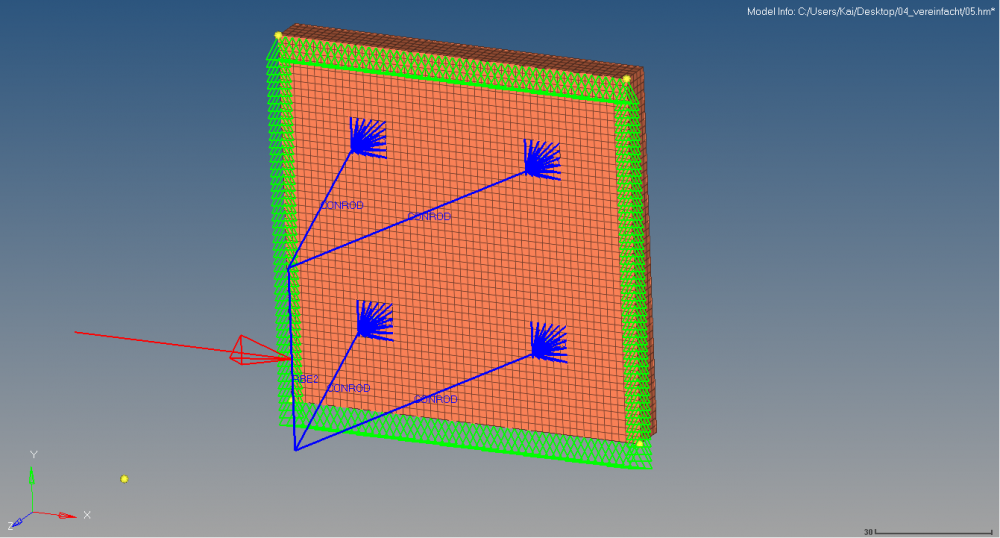

at the moment I'm doing some tests for an upcoming optimization. I use HM 14.0 with Optistruct.

I want to simulate a simplified suspension.If I model the suspension rods with CONROD-Elements, the following error message appears:

*** ERROR # 153 ***

Exactly zero pivoting encountered during Numerical Factorization;

the model may have rigid body mode.

Solver error no. = -503

spc set id = 1

index = 1

Possible reasons are:

1) insufficiently constrained model,

2) having rigid body mechanisms within the model,

3) extremely ill-conditioned rigid element sets,

4) extremely thin shells (as used for skinning) that have MID2/MID3,

5) gap elements with extremely high stiffness (KA, especially KT or MU).

Check the model and rerun the problem.

(MECHCHECK may be used to find the rigid body modes. To do so,

change the input to be an eigenvalue analysis and add MECHCHECK.)

(WARNING: results obtained with MECHCHECK cannot be used because

the model is changed internally.)

This error was detected in subroutine bcsmtxfct.

If I turn MECHCHECK on, the max. displacement is 0.008061 mm.

When I replace the CONROD Elements with nearly stiff CBEAM Elements, the error message disappears. The max. displacement is 0.00769227 mm.

To my knowledge, the suspension rods are just tension and compression rods.

Could you help me, why I get the error message? I attached the file.

Best regards,

Kai

<?xml version="1.0" encoding="UTF-8"?>