Hi @Prakash Pagadala,

I have two issues to solve.

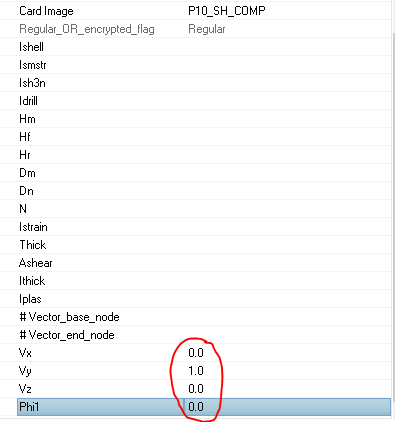

1) I don't know how to define material orientations successfully. I have seen many forum questions about this issue. I cannot define material properties as in Optistruct (2d - composite - material properties - define a base vector). In property type10 SH_COMP I have defined the vector which should be the 0º direction. Is this correct? It doesn't seem to be correct when I try to visualize it with the option 'Composite Layers with Fiber Directions'.

2) Error 495 shows up when I run CHECK option.

- Material law25 COMPSH is defined.

- Property type10 SH_COMP is defined.

- In the reference guide says this pair should have compatibility.

Thanks in advance.