Hi there,

I'm new to lattice optimization and confronted a curious problem.

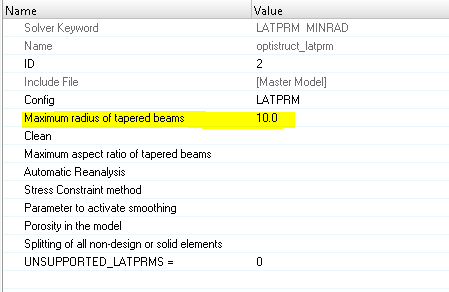

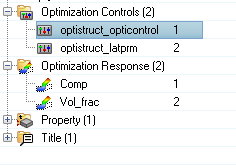

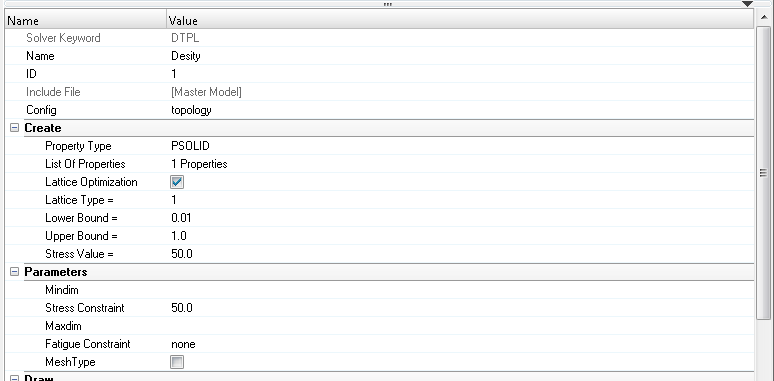

My test example is a cubic, with dimension 240mm*146mm*1000m for example, after state analysis, the max displacement is about 7.5mm. Then I did lattice optimization, set volume_fraction as constraint and Min_compliance(Max stiffness) as objective. I set the density as Design_variable, with range 0.01~1, as shown in pic attached. And I have two control cards to set optimization process.

My three questions are:

1. What should I choose for 'Config' for these two cards respectively? One just controls interation number and the other control lattice parameter?

2. When I set minimum of lattice radius value, for example10mm, it appears as the maximum radius value in the control card. Why does this happen?

3. Is it possible for me to have a lattice optimized structure having same stiffness(max disp) as the original solid one? And How? Is it possible to achieve it just by changing lattice radius?

Great thanks!

<?xml version="1.0" encoding="UTF-8"?>

<?xml version="1.0" encoding="UTF-8"?>

<?xml version="1.0" encoding="UTF-8"?>