<?xml version="1.0" encoding="UTF-8"?>

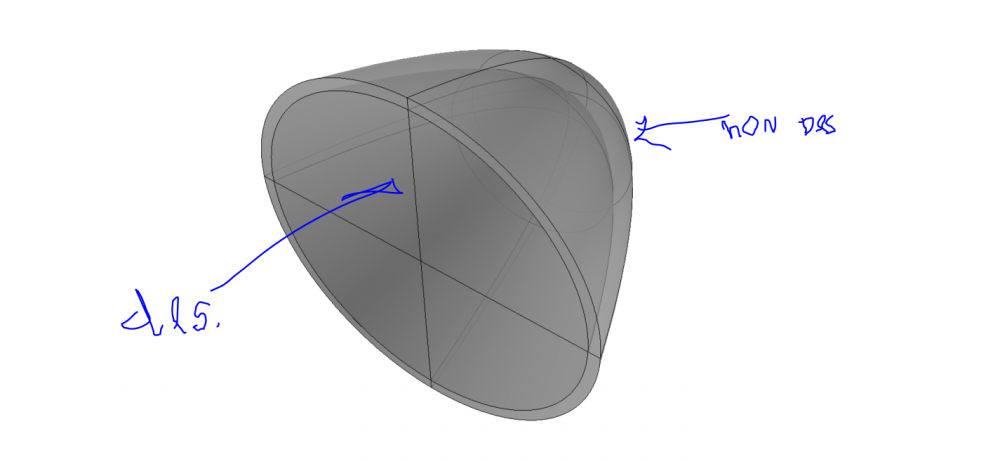

Hello, does anyone know how to select non design space for a cone? to perform topology optimisation.

It is a cone subjected to pressure.

And, is it also possible to model in CAD and select solids? Creating a component for non design space while having muliple solids does not work.

<?xml version="1.0" encoding="UTF-8"?>

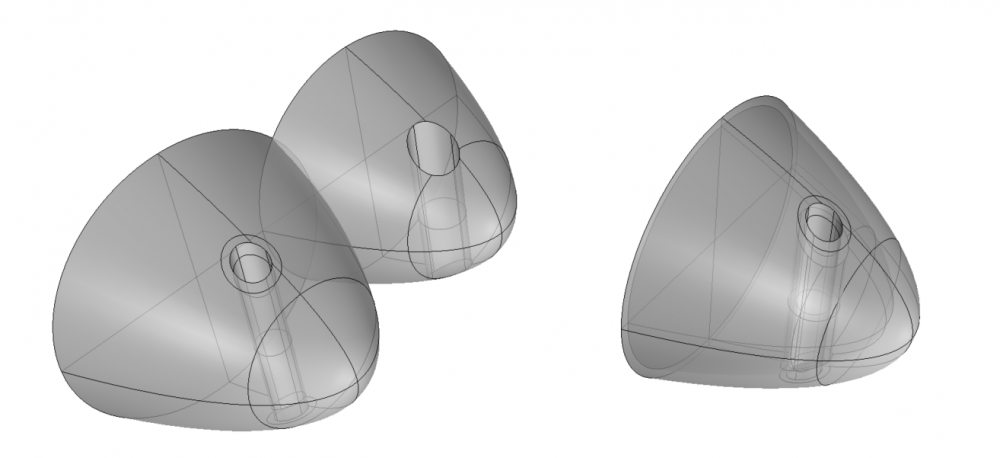

I also want to do this with openings included

Thanks in advance,