Hello,

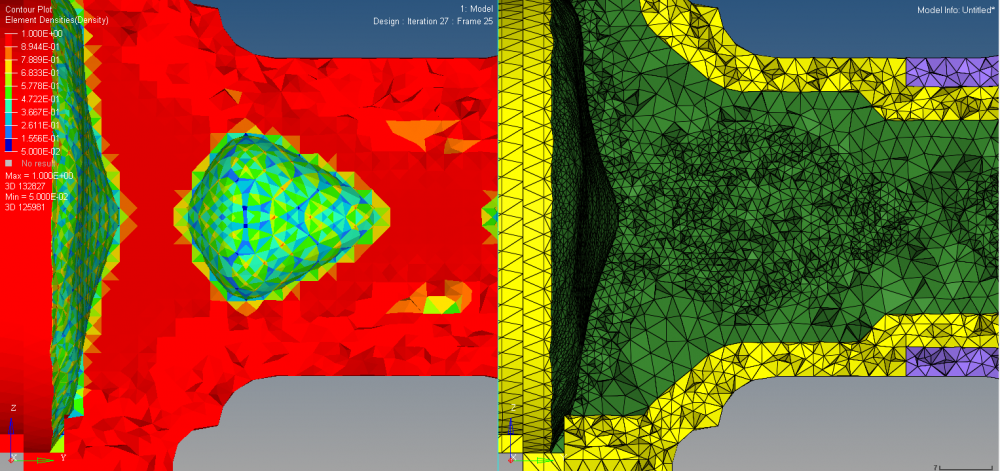

I am currently optimizing topologically a part and after the optimization I can see a hole created in my part.

But when I am doing the OSSMOOTH operation for FEA Re-Analysis, the hole is filling with small element with doesn't correspond to my optimized model (as you can see on the pictures in attachments).

Moreover if I am trying to do a FEA Re-Analysis with the 'bad-optimized' model, I will have the following message:

Element # 1273589, element type TETRA.

*** PROGRAM STOPPED: ERRORS DURING ELEMENT QUALITY CHECK.

Could you help me with that problem ?

Thanks

<?xml version="1.0" encoding="UTF-8"?>