Hi all,

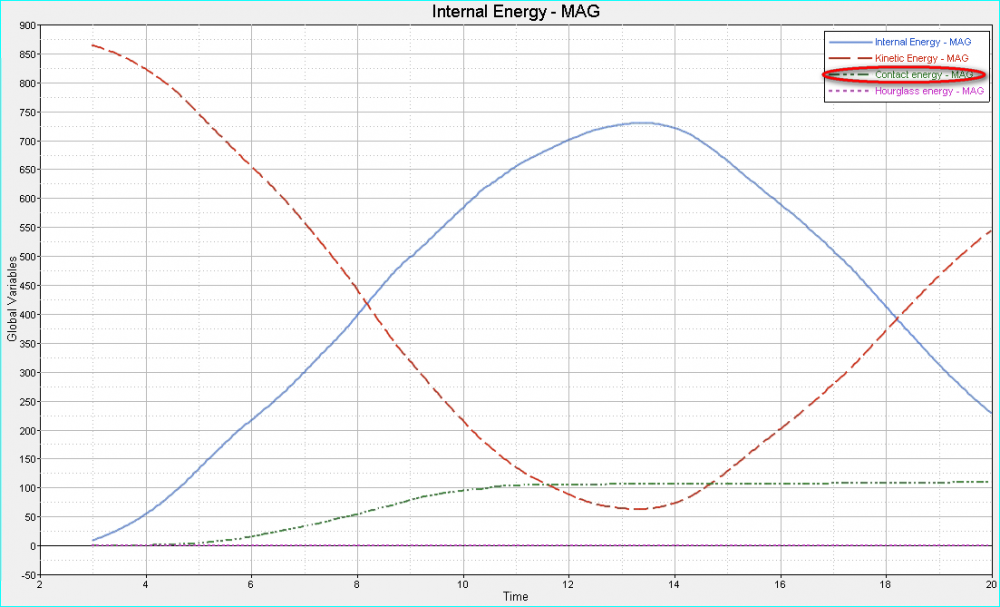

In my model, there are many contacts. From the result, I found the contact energy was large. How can I find which contact makes the large contact energy? In LS-DYNA, each contact energy can be output separately. However, in Radioss, it seems that we can only output total contact energy through global variables.

<?xml version="1.0" encoding="UTF-8"?>

Best Wishes

Roy