Hello All,

Thanks for clearing all my previous queries,

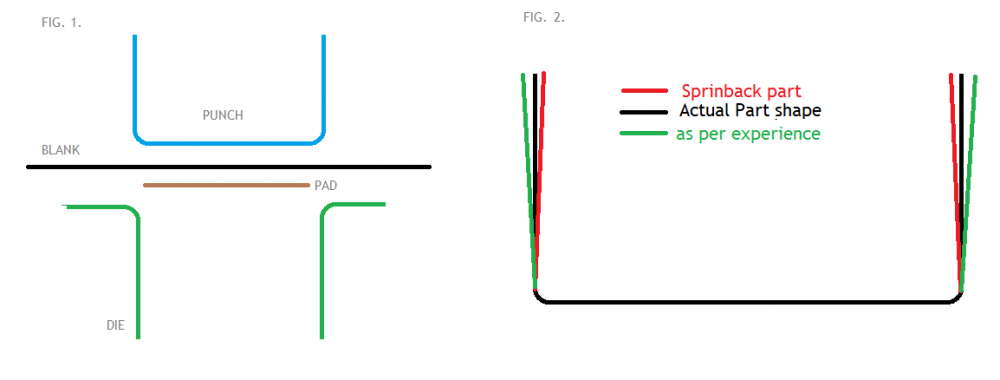

Here after many trials of springback simulation using all possible ways of the springback setup (i.e. Using automatic/manual/ auto process/advance tools/multistage). I have found the unacceptable spring back results that , in case of a hat section.

Here as shown in fig 2. the hat section part after forming-springback the part is going inside (-ve springback, which is unacceptable), i.e. if we bending/forming/flanging a part with 90° it will be springback with the bend angle as 90°+1or2 degree, but springback bend angle will be always greater than the bend angle.

But in this case the springback is showing as shown in FIG 2.

Image contains 1. springback part, 2. Actual Part, 3. As per the actual forming procedure

Please help me what should I do to evaluate the springback, You can take any Hat section part & form it using Pad ( since it is my Design requirement shown as in fig 1)

Please reply,

<?xml version="1.0" encoding="UTF-8"?>