Hi there, hope someone can help me.

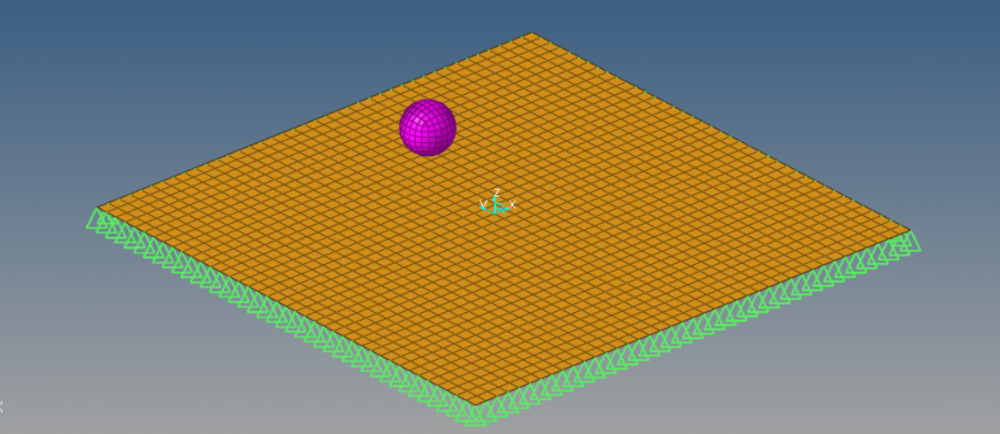

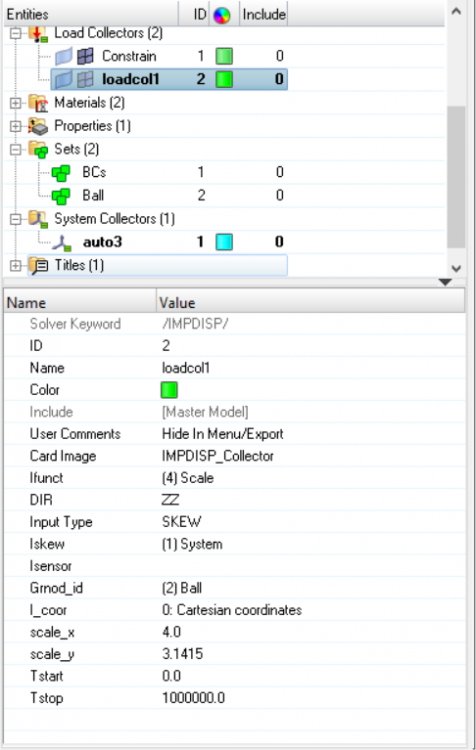

I am trying to make this ball rotate around the Z axis of the local coord. system created by me (skew in the middle of the plate). I don't know why, but the ball keep spinning around its own Z axis. I already tried creating RBody, cylindrical system, changing from /Skew to /Frame... nothing of that worked, it always rotates around its own axis. What am I doing wrong?

<?xml version="1.0" encoding="UTF-8"?>

<?xml version="1.0" encoding="UTF-8"?>

Thank you.