Hi everyone.

My name is Mirko and i'm working on my final thesis in Aeronautical Engineering at the Politecnico of Milan.

My thesis is about an aeronautical seat and i'll have to use Hypermesh to mesh the parts of the seat in order to use them in FE analysis; unfortunately i'm a new user of Hypermesh and i cannot find tutorials or guide helpfull for my problem.

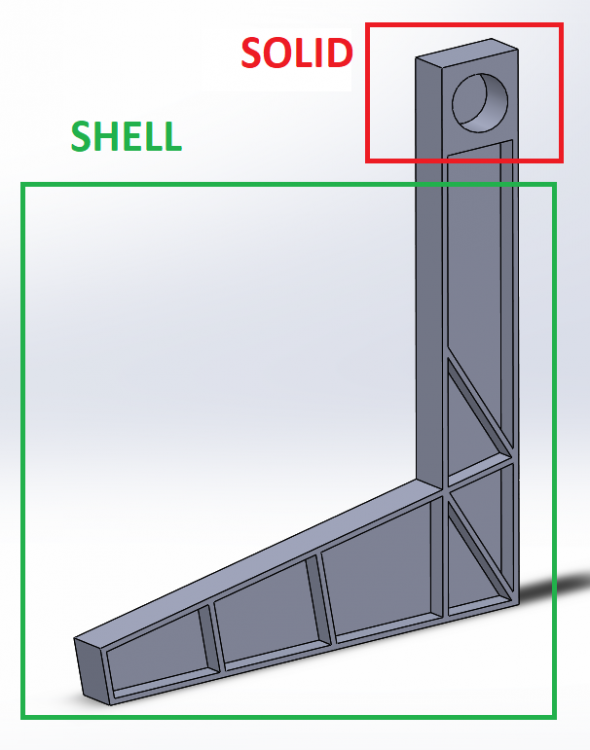

I have to create the mesh of the 'legs' of my seat, but they are made of thin surfaces and of one solid block at the top; in a first approximation i've neglected the solid part and i generated middle surfaces and meshed them as shell, but now i have to consider also the solid part.

There is a way to create a mixed shell Shell+Solid? Or i'll have to mesh the entire body as Solid?

Thank you very much in advance for your help.

<?xml version="1.0" encoding="UTF-8"?>