Hi

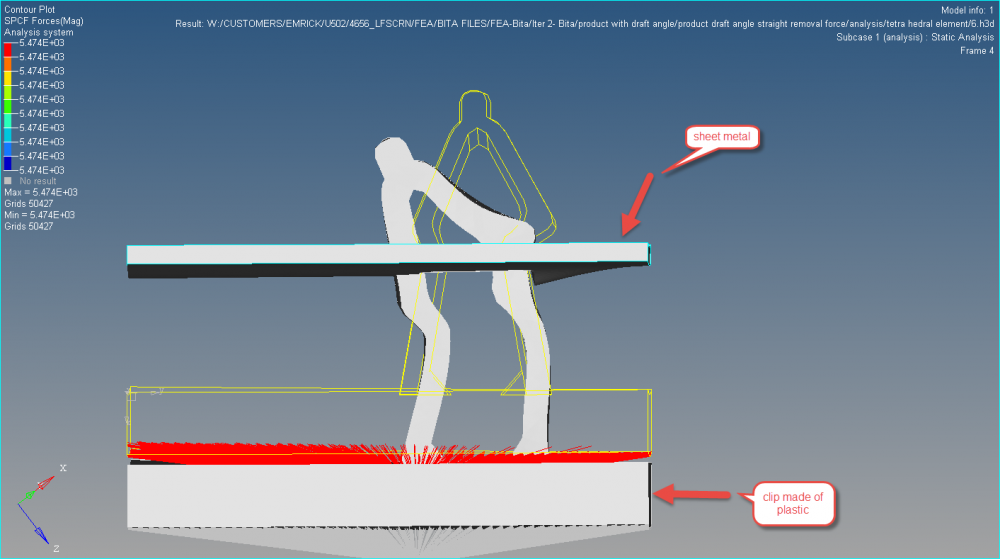

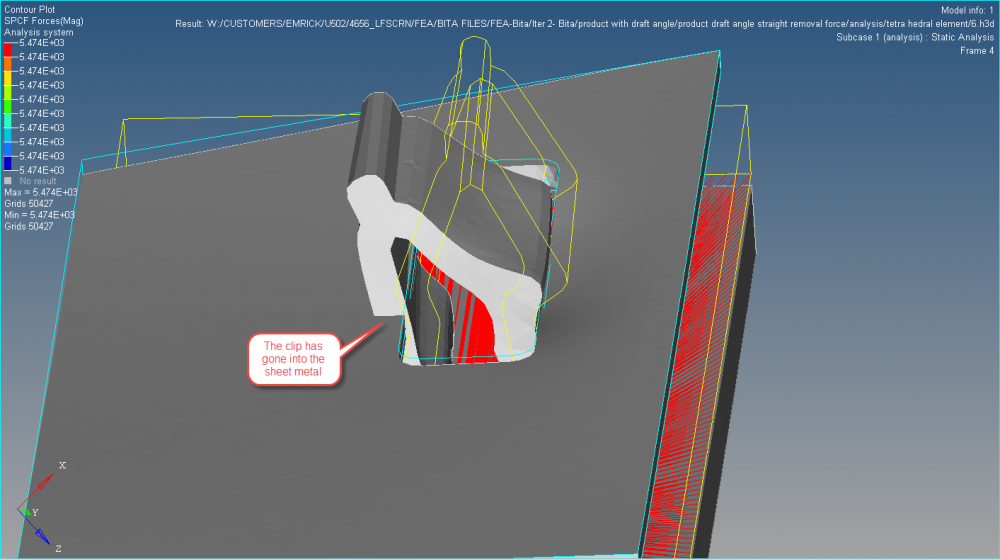

I have done this modeling in optistruct (an enforced displacement is applied to the back of plastic clip and required force for this this displacement is asked) but when I run the model and post process it in Hyper view I see the the clip penetrates in to the sheet metal. I think this penetration makes the results invalid. Would you please let me know what is wrong with this modeling. The model is attached

![]()

I have defined contact between all these surfaces but I don't understand why it behaves like this

<?xml version="1.0" encoding="UTF-8"?>

<?xml version="1.0" encoding="UTF-8"?>

Unable to find an attachment - read this blog