Hello Everybody,

I am trying to bring a good quality hexa mesh. The mesh I am getting is good in almost all the quality criteria except 'aspect ratio'. I am getting the aspect ratio values in range 3 to 5. I have read that the acceptable aspect ratio is below 5, so my mesh should work. But what I am expecting is to get a good quality mesh in the area since it may be the region of high stress. My question is how good my mesh is if it is to rate between 1 to 10? (I am getting a very good mesh for rest of the quality criteria) And to what extent my results may get affected if I fail to bring a proper mesh in the region?

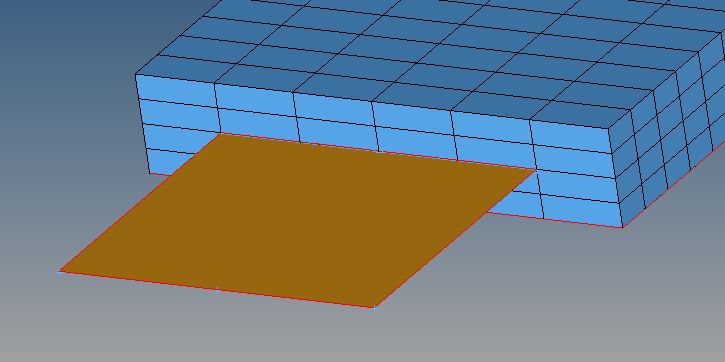

The attached illustrative image may be referred. The 3D mesh will be connected to 2D mesh and the the analysis is explicit (Radioss).

Please advise.

<?xml version="1.0" encoding="UTF-8"?>