Good Afternoon Everyone,

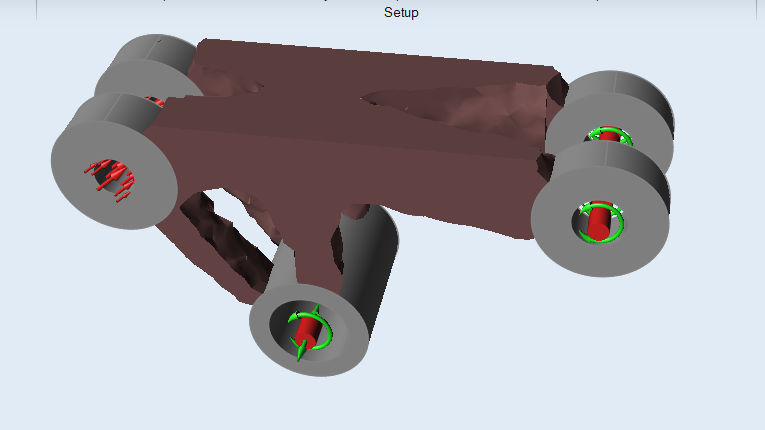

I have a bit of a noob question for y'all; I'm trying to optimize a bell-crank for a racecar suspension and am struggling to properly constrain it. I have tried a few iterations, the first with a force being applied to one side of the bell-crank (input from push rod), with the opposite side (shock connection) fixed. I then applied a rotational constraint to the pivot point which doesn't really make sense if the shock connection is fixed. While this does output a model, it doesn't appear to be correct. I have attached a picture showing what I currently have from this iteration. If I apply a force on each side, I get a displacement error.

If someone could shed some light on what constraint to use for the shock side of the bell-crank or even point me to some documentation on this, I would greatly appreciate it.

Thanks,

Boost

<?xml version="1.0" encoding="UTF-8"?>