Hi everybody.

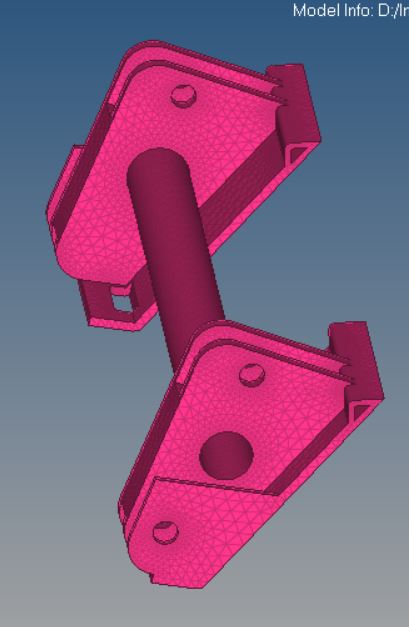

I am designing a rapid attach system for the bucket of a skid steer loader (see picture below), taking inspiration from the commercial systems.

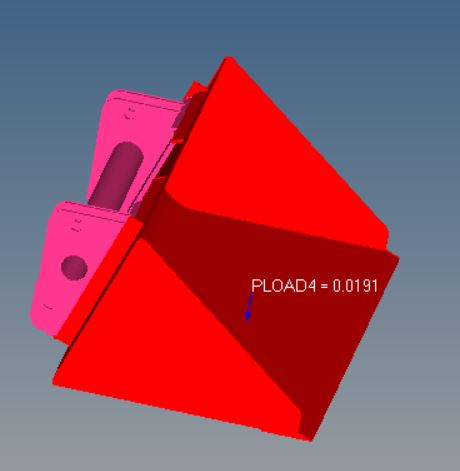

In the second picture you can see how this system work: there a contact surface between the bucket and the tach.

So there is a contact zone and of sure I should do a non-linear quasi static analysis; however since I would not do a non linear analysis I ask you if there is another way to get a solution.

I've already done a non linear analysis but I can't validate the results since this kind of analysis should be quite instable. So I'd like to find another way (with linear analysis) just to compare the results.

Thanks in advance for your help

Best Regards

Stefano

<?xml version="1.0" encoding="UTF-8"?>

<?xml version="1.0" encoding="UTF-8"?>