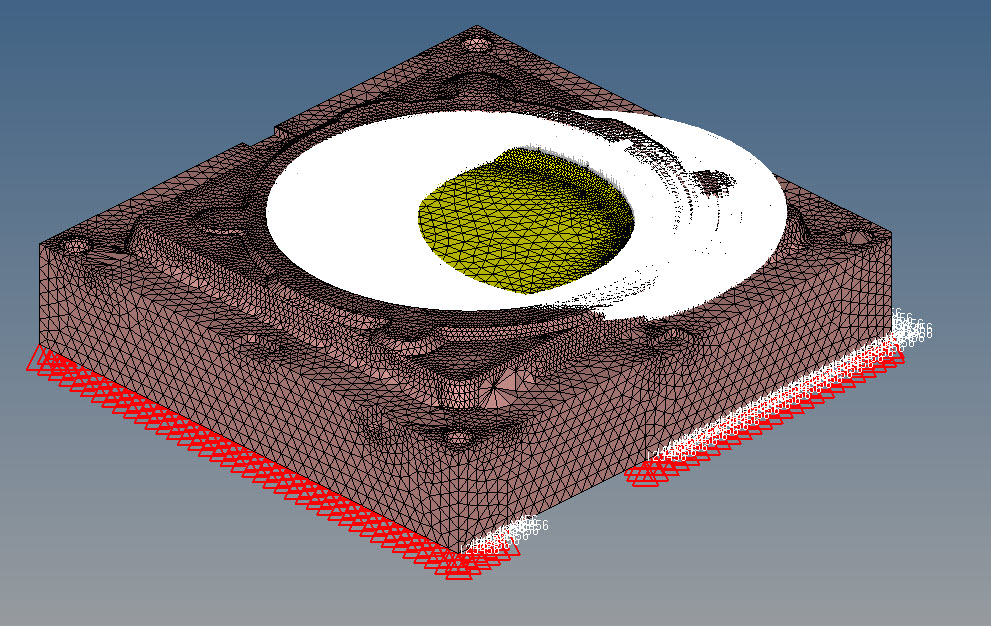

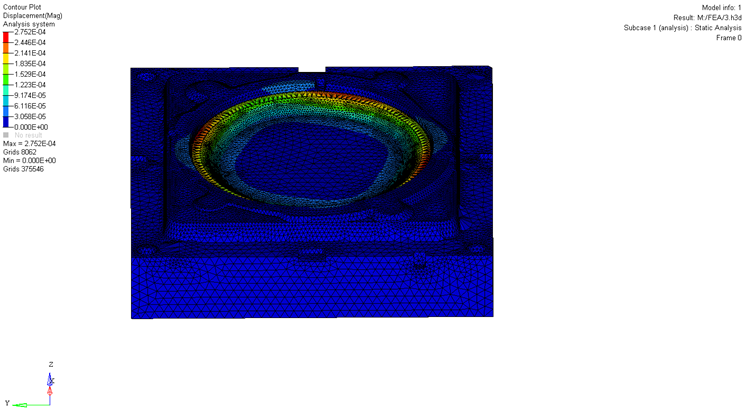

I have a part like following the back plate is constrained and pressure is applied to a round surface on top. I have done linear static analysis. and found the deflection, as follow

mac displacement= 2.7 mm

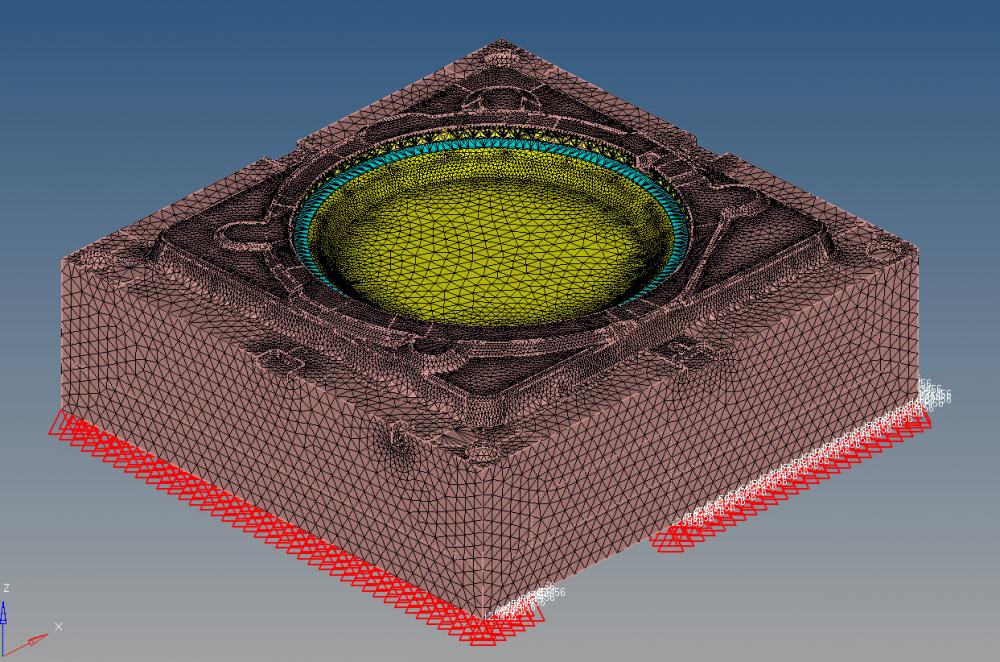

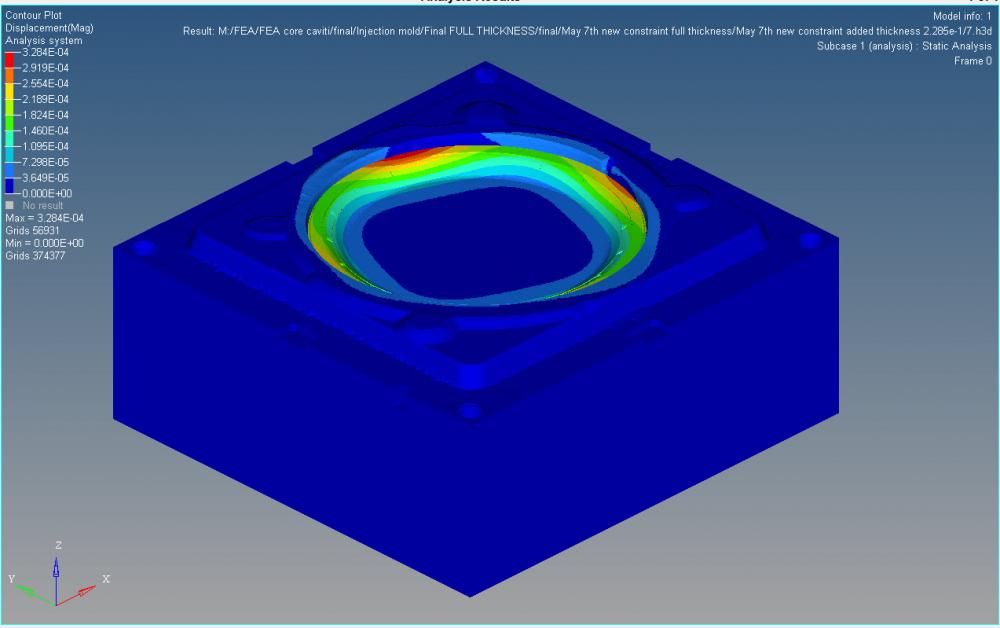

I have doubled the thickness pressure and constraints are the same as previous one

<?xml version="1.0" encoding="UTF-8"?>

bu the maximum deflection has increased while I expected to have decrease in maximum deflection since I have doubled the thickness and I have more stiffness

Max displacement = 3.2 mm

<?xml version="1.0" encoding="UTF-8"?>

I was wondering what can be the reason ? What should be the trend of maximum displacement?? by increasing the thickness should I expect increase in maximum deflection or decrease??