Dear All,

I'm new to HyperForm. Want to predict spring back, % thinning of the blank.

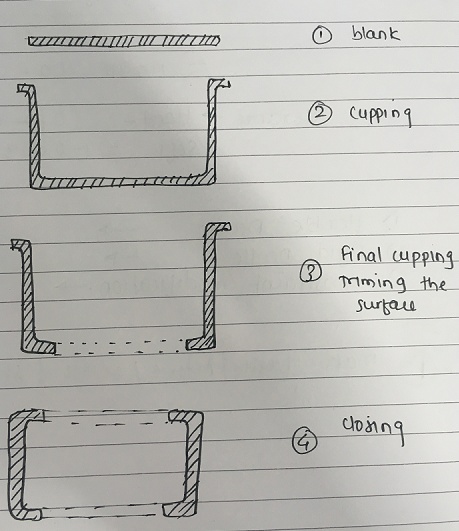

process of manufacturing closed ring is mentioned in the image below, Please revert with the same.

I have blank, punch and die model of every stage

If anyone worked on similar kind of simulation, please revert with simulation process.

processes are as follows,

1. blanking, where blank of required size is to be cut.( i have solid model of both punch and die)

2.cupping, where forming of blank is done wrt punch and die dimenssions

3. trimming, where central portion of formed part is cut off.

4. closing of upper lips.

want to check spring back, wrinkles(if present) and % thinning at every stage. and how can i compensate spring back in to die or punch design.