Hello,

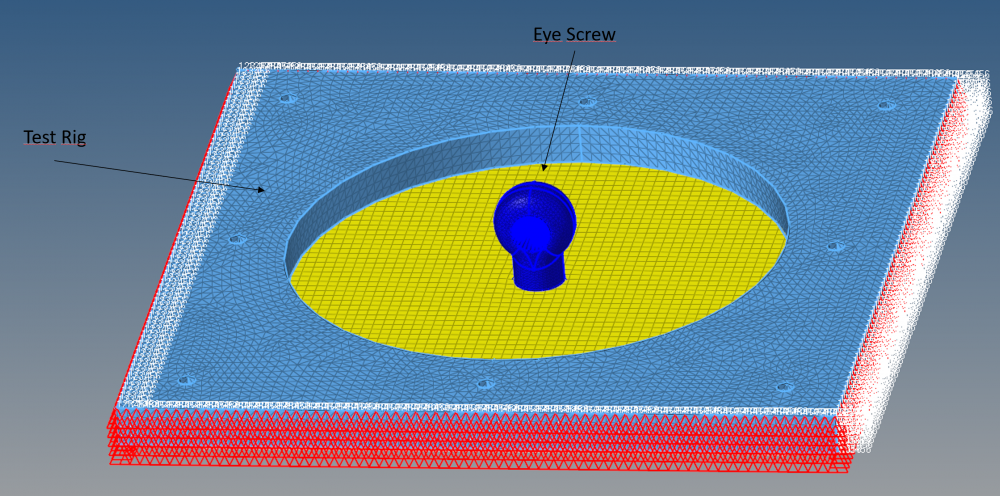

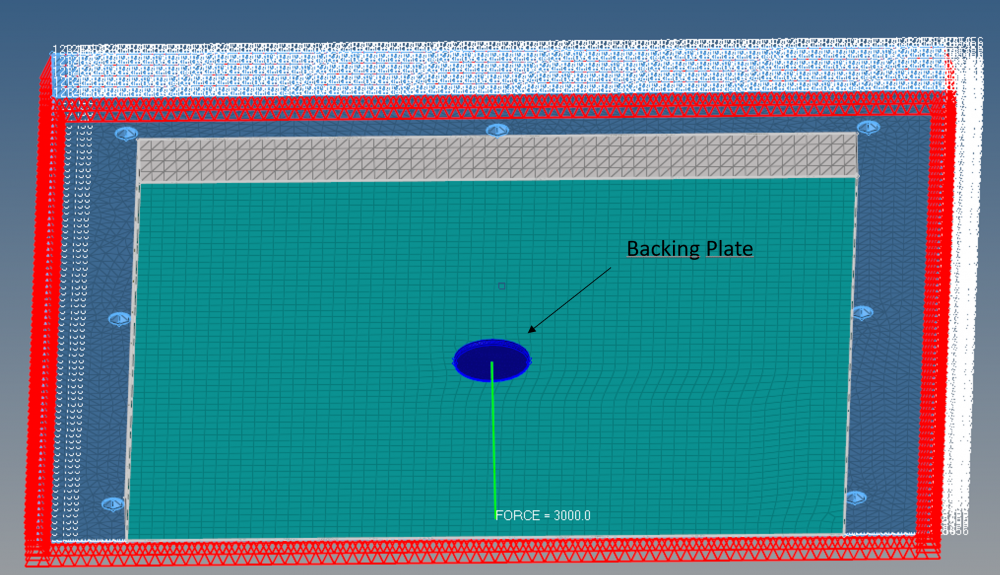

I am simulating a pull out test.

I built my model in accordance to some tutorials using a 3D mesh with mat9ort and PSolid to the honeycomb and two 2D mesh to the carbon fiber layers with mat8 and Pcompp.

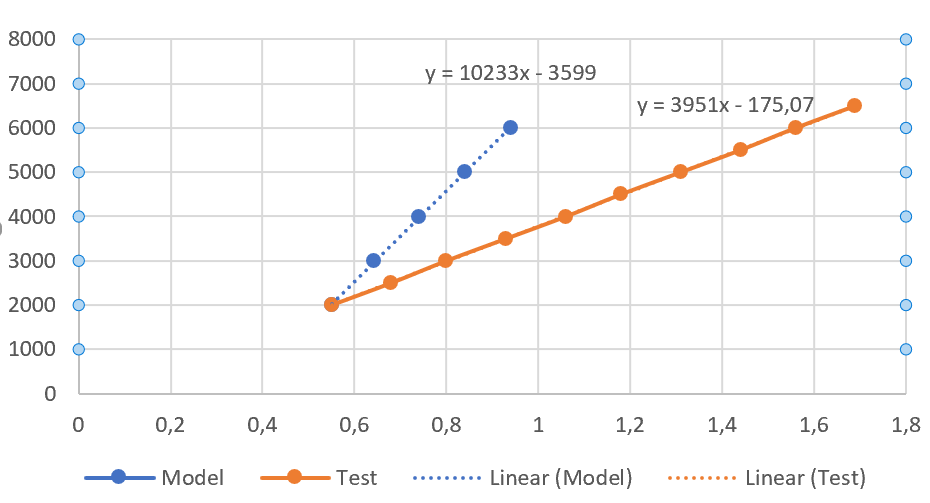

After the model is running i made a test specimen and test it. The problem is that my model is much more rigid than the real life (see the graph).

To apply the force i use an eye screw and a backing plate that i had modeled too and used some contacts between the test rig and the plate and between the backing plate and the sandwich plate. These are the only constraints applyed to the sandwich plate.

Could someone help me with this? I dont know why there is this difference between the model and the real test

Attached is the model

<?xml version="1.0" encoding="UTF-8"?>

<?xml version="1.0" encoding="UTF-8"?>

<?xml version="1.0" encoding="UTF-8"?>

Unable to find an attachment - read this blog