Surface Miner Simulation and Analysis with Altair EDEM and Altair OptiStruct

What is Continuous Surface Mining?

Surface mining is a process of removing the soil and rock covered by mineral deposits without drilling and blasting. The cut material is pre-crushed and sized before being conveyed downstream.

Benefits of Continuous Surface Mining

- High productivity and low cost

- Drilling and blasting is not required

- Crushing and sizing before conveying onto the truck

Surface miner blades play a key role in bulk material cutting and due to this, the blades are subjected to wear, the wear in surface miners is dominated by abrasive and impact wear mechanisms and the blade wear will greatly reduce the cutting efficiency of the surface miner. These blades are difficult to repair, and the replacement cost is high.

Simulation and analysis of the surface miner with Altair® EDEM™ and Altair® OptiStruct® (OS) allows engineers to investigate the action of abrasive particles on the equipment. This provides a theoretical basis for design of the surface miner for improved wear resistance performance. In addition to wear, EDEM also helps to optimize the process parameters such as:

- Linear translation velocity of the drum

- Angular velocity/RPM of the drum

- Bulk material cutting depth

- Durability of the drum and Teeth

Prerequisites

EDEM-OS 2-way coupling via the Altair® SimLab® interface supports the software version specified below or later versions

- EDEM – 2024

- OptiStruct – 2024

- SimLab – 2024.1

Simulation Setup - Key Points

This EDEM+OS 2-way coupling surface miner demonstration case is applied to a sample model using a generic EDEM material model for the rock. The material is not calibrated and uses the relative wear model. Representative process parameters such as linear velocity and rpm of the drum are applied.

This example will help the user get familiar with the following:

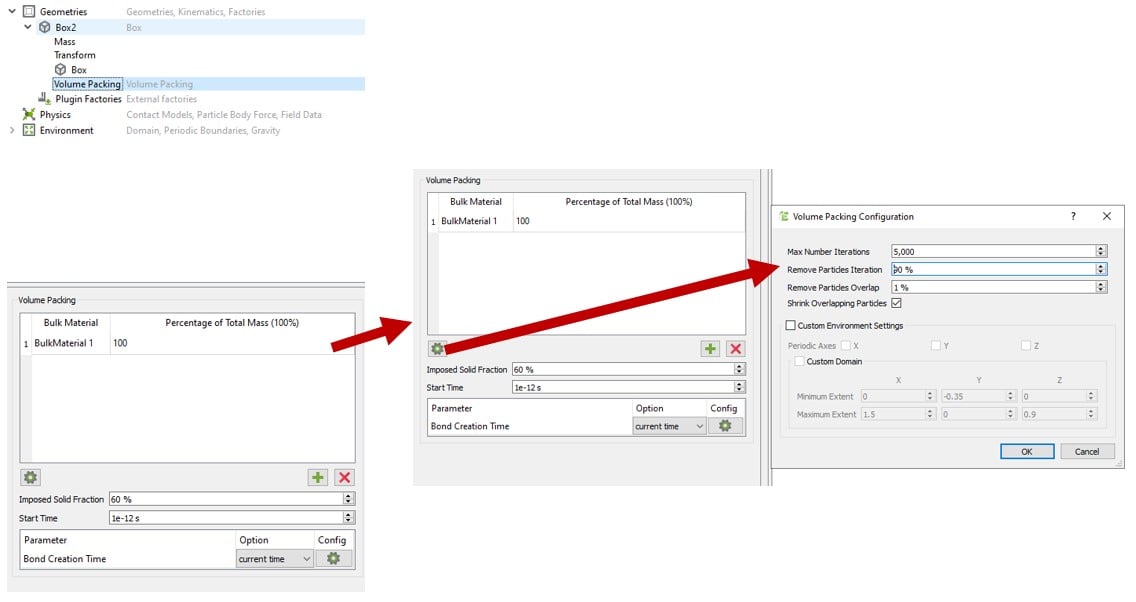

- Creating a bulk material bed using volume packing

- Finite element modeling using SimLab such as

- Meshing of CAD geometry

- Defining Time-dependent motions

- Constraints

- Defining wear models

- Solving EDEM+OS, Co-simulation

In case any user tries to validate the simulation results with an experimental test then the user has to use a calibrated material model and appropriate process parameters.

- Create and EDEM Material Model including Bulk material properties, particle-to-particle interaction, particle-to-geometry interaction, particle shape, size, etc.

- Create a Box (X=300mm, Y= 250mm and Z= 500mm) in EDEM

- Transform Box to X= 1350mm, Y= -125mm, Z= 350mm

- Define Physics models such as Hertz-Mindlin no slip, Standard Rolling Friction, and Bonded_V2

- Define Bonded_V2 parameters

- Define factory setup and Bond creation time as shown in the below picture

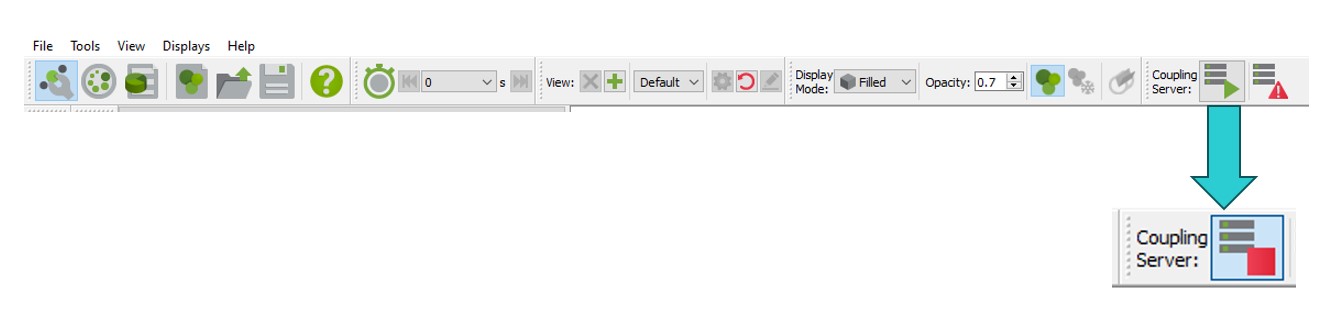

- Switch on the coupling server shown in below picture

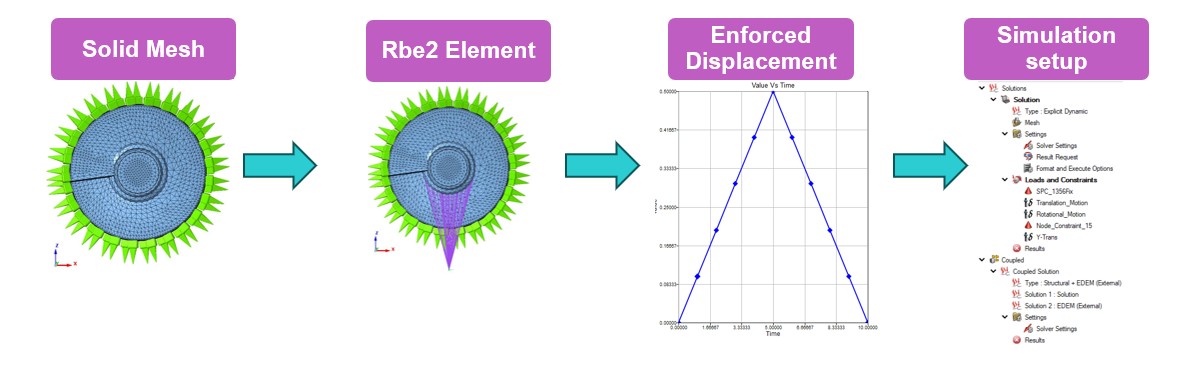

- Import the .fem into SimLab

- Create an Rbe2 element

- Create Explicit simulation

- Define Simulation settings

- Define Result Request

- Define Format and Execute Options

- Apply translational motion on the Rbe2 element (Forward and Backward Motion)

- Apply rotational motion on the Rbe2 element

- Apply lateral translational motion on the Rbe2 element

- Define Constraints

- Create a Coupled simulation

- Define Coupling Time Step

- CAD: SurfaceMiner_CAD.stp

- FE Mesh: SurfaceMiner_Training.fem

- FE model: EDEM_Deck.zip

- SimLab File: SurfaceMiner_Training.slb

OS Simulation Deck Setup

Simulation Results

For more EDEM applications please see our EDEM Webinars:

To get started with EDEM: