Hi,

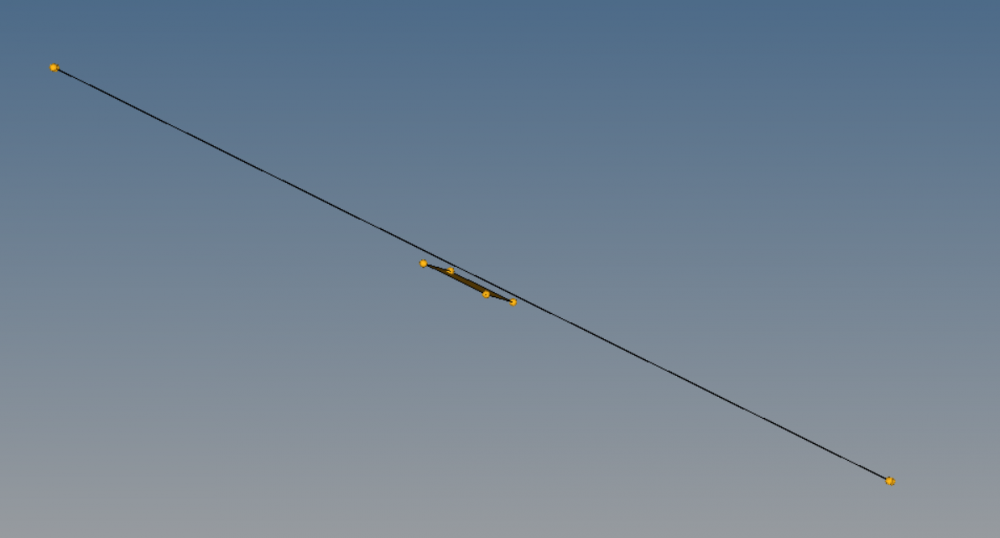

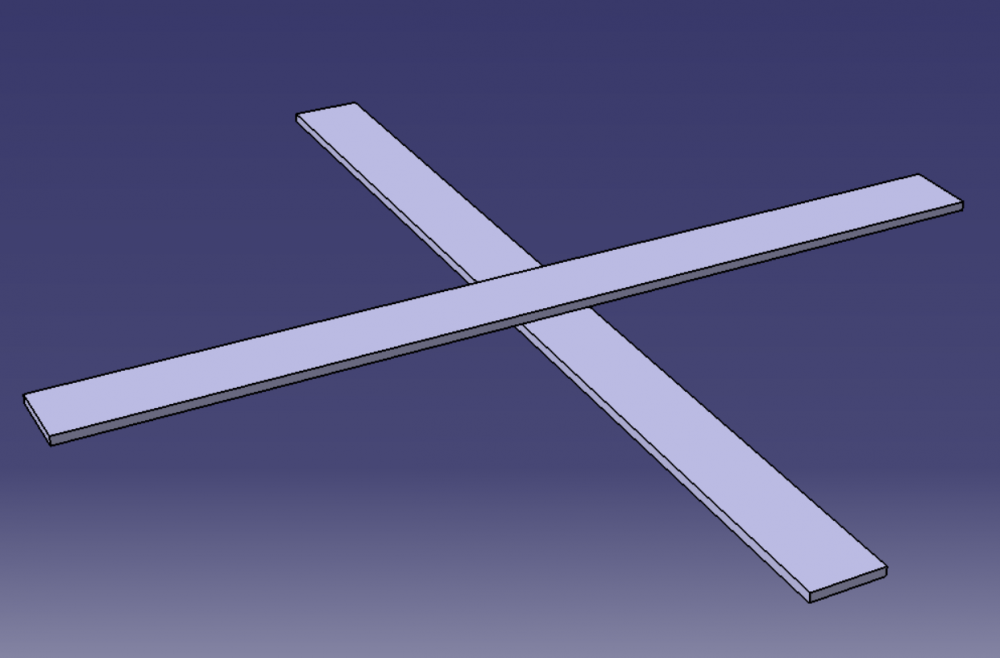

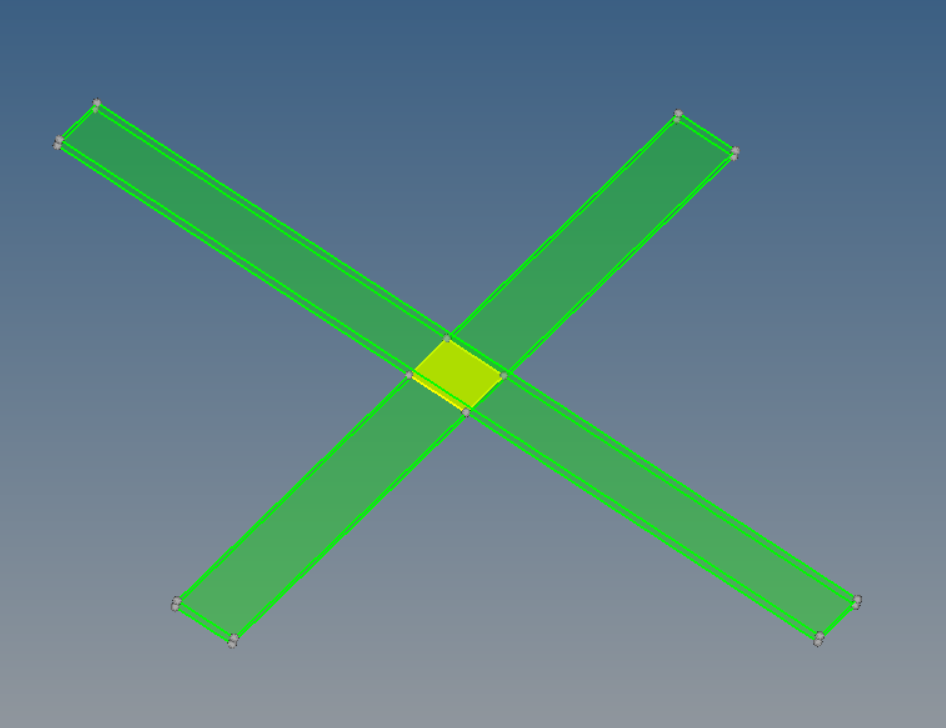

I’m a beginner with altair Hypermesh and today I try to connect two parallel surfaces together. those midsurfaces are exctracted from the model shown below (the plates are considered to be welded together in reality).My goal is to mesh those surfaces and recreate the contact in yellow shown on the second picture. For the moment, due to the mid-surface extraction, I have a gap between the two planes. should I use RBE2/RBE3 elements to connect them ? My goal is to have a contact that behave as much as possible as if the two planes are welded. ![]()

![]()

![]()

Thank you very much for the help![]()

![]()

![]()

<?xml version="1.0" encoding="UTF-8"?>

<?xml version="1.0" encoding="UTF-8"?>

<?xml version="1.0" encoding="UTF-8"?>