Hello,

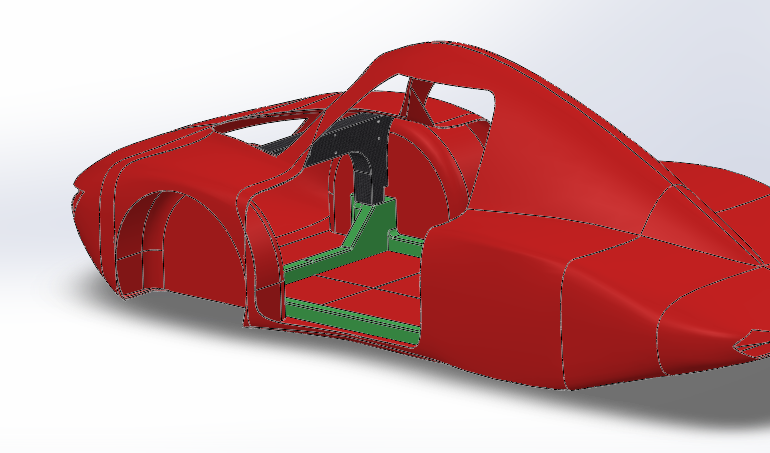

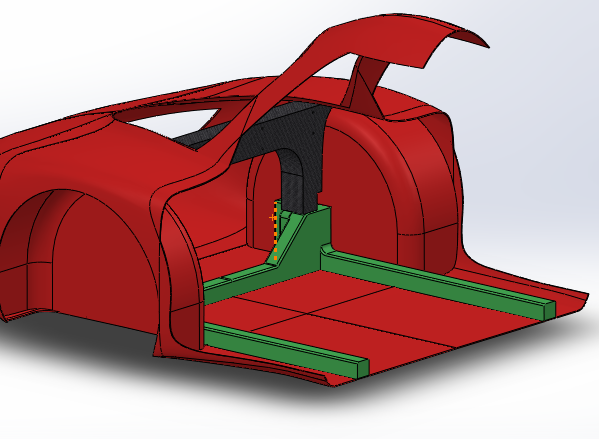

I am trying to analyse and optimize the chassis of a composite car. The body will be made out of woven carbon fiber and aluminium honeycomb but at the same time, to add stiffness, there will be spars and a dashboard made out of PVC foam, layered with carbon fiber to add to the structural strength and torsional stiffness of the vehicle. Here is a picture

![]()

As you can see, the blackish/gray is the dashboard, the green are the spars and the red is the body.

So what I did was I imported all 3 files together. Since I've made these parts in relative to each other, they fit perfectly without having to 'mate' anything in Optistruct as you would do in Solidworks.

The problem arises when I try to upload the body AND the spars/dashboard together.

The body was originally a full solid used to run CFD. Later, it was shelled in solidworks so it was hollow but still had a thickness. This would be a problem is I were to try to layer carbon fiber on it.

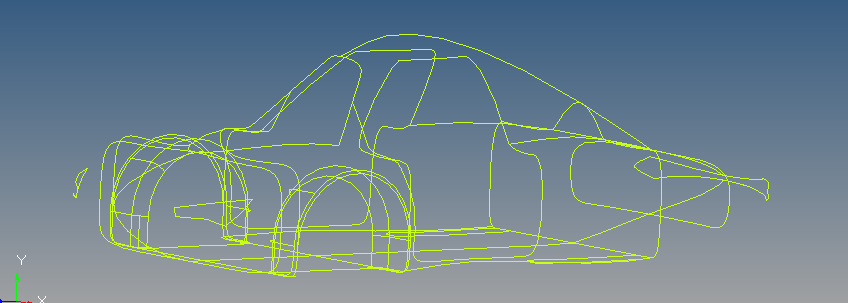

So what I did was that I uploaded it to design modeler, thinned all the surfaces and I achieved a pure surface body, which was perfect for layering carbon fiber.

However, it seems that when I try to upload the surface body together with a solid body, the surface body disappears.

Everything is fine when I upload the surface body.

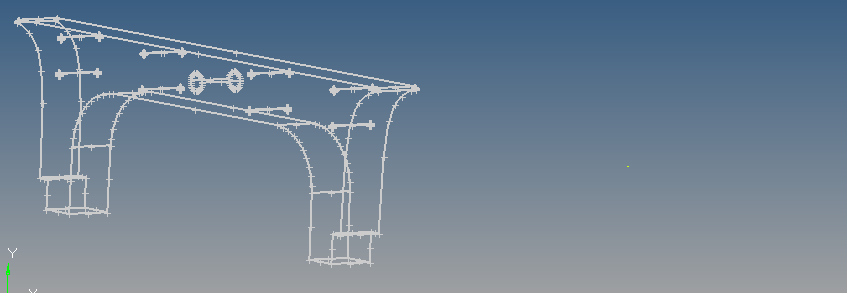

Now when I try to upload the dashboard,

the surface body disappears and only the solid body remains.

Does anyone have any ideas how to get around this?  /emoticons/default_sad.png' srcset='/emoticons/sad@2x.png 2x' title=':(' width='20' />

/emoticons/default_sad.png' srcset='/emoticons/sad@2x.png 2x' title=':(' width='20' />