A hydraulic hammer, also known as a hydraulic breaker, is a powerful tool attachment for excavators and other construction equipment that uses hydraulic pressure to deliver high impact blows for breaking bulk material such as concrete, asphalt, and rock.

Objective:

Simulating rock breakage using a hydraulic hammer with EDEM + MBD is a powerful way to study how rock responds to dynamic impacts. Simulate the impact of a hydraulic hammer on a rock block or bed to analyze:

- Rock Breakage

- Impact forces

- Chisel wear

Challenges:

The following are the key challenges

- Structural Strength of the parts

- Forces required to break rock

- Wear of the chisel

- Costly to do physical testing

Key Points to be Noted:

- Generic CAD model is used to model the hydraulic hammer

- Non-Calibrated rock material model is used in the simulation

- Simulation files shared are generic and Demonstration purpose

- The result from simulations should not be used to validate/correlate with test results

EDEM Simulation Setup:

The following steps to be followed to create the rock

- Define the bulk material properties

- Define the Particle to Particle and Particle to geometry Interactions

- Define the particle shape, size and its distribution

- Import rock geometry using .stl files

- Transform the geometries as per the position in EDEM deck

- Create a volume packing with 60% solid fraction

- Define Particle-to-Particle and Particle-to-Geometry as HM-(No-Slip) physics model

- Define BondingV2 in Particle-to-Particle interaction, the stiffness parameter to be used from EDEM deck

- Define the simulation setup such as

- Raleigh Time Step = 10 %

- Simulation time = 18 sec

- GPU solver with CPU’s=6

- Run the Simulation

- Export the Simulation Deck at time step = 18 sec

- Open the Exported simulation deck

- Delete the volume factory

- Update the rock geometries are virtual or delete the rock geometries

- Switch on the coupling server

MotionSolve Simulation Setup:

- Multi-Body Dynamics model built using MotionSolve and appropriate kinematics are defined

- The setup file is attached in this page

- MotionSolve setup file is a demonstration model and should not be compare the results with any of the experimental results

- Please find the below links to know more about MotionView/MotionSolve

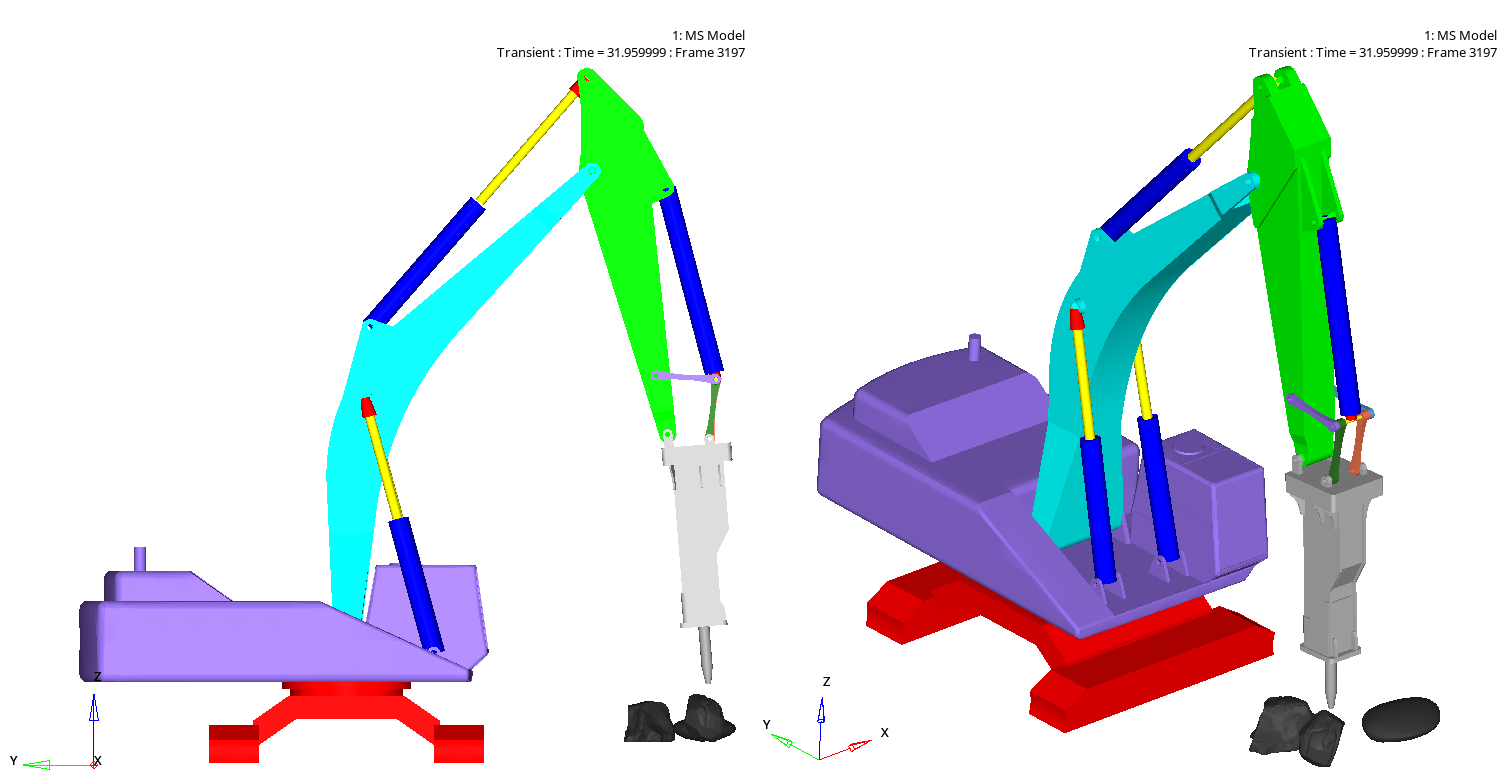

Simulation results:

*Note:

The rock breakage simulation involves the breaker moving from its initial position to engage with the rock, followed by the breakage process. During this initial phase, EDEM does not transfer any forces or responses to MotionSolve, as there is no interaction between the particles and geometry. A full-time coupling between EDEM and MotionSolve from time = 0 seconds would significantly increase computation time. Therefore, in this simulation, the co-simulation is initiated just before the breakage phase—specifically at 18 seconds. Until this point, MotionSolve runs independently, and at 18 seconds, the updated geometry position is transferred to EDEM. From that point onward, the EDEM–MotionSolve coupling is activated and continues through the breakage event

The computation time reduced due to this method of coupling is 50%.

The Prerequisite to do this method of coupling is

Step-1:

EDEM simulation to be run to the time at which coupling to be established i.e in this simulation EDEM simulation runs till 18sec and exported the deck as 18sec instead of 0 sec

Step-2:

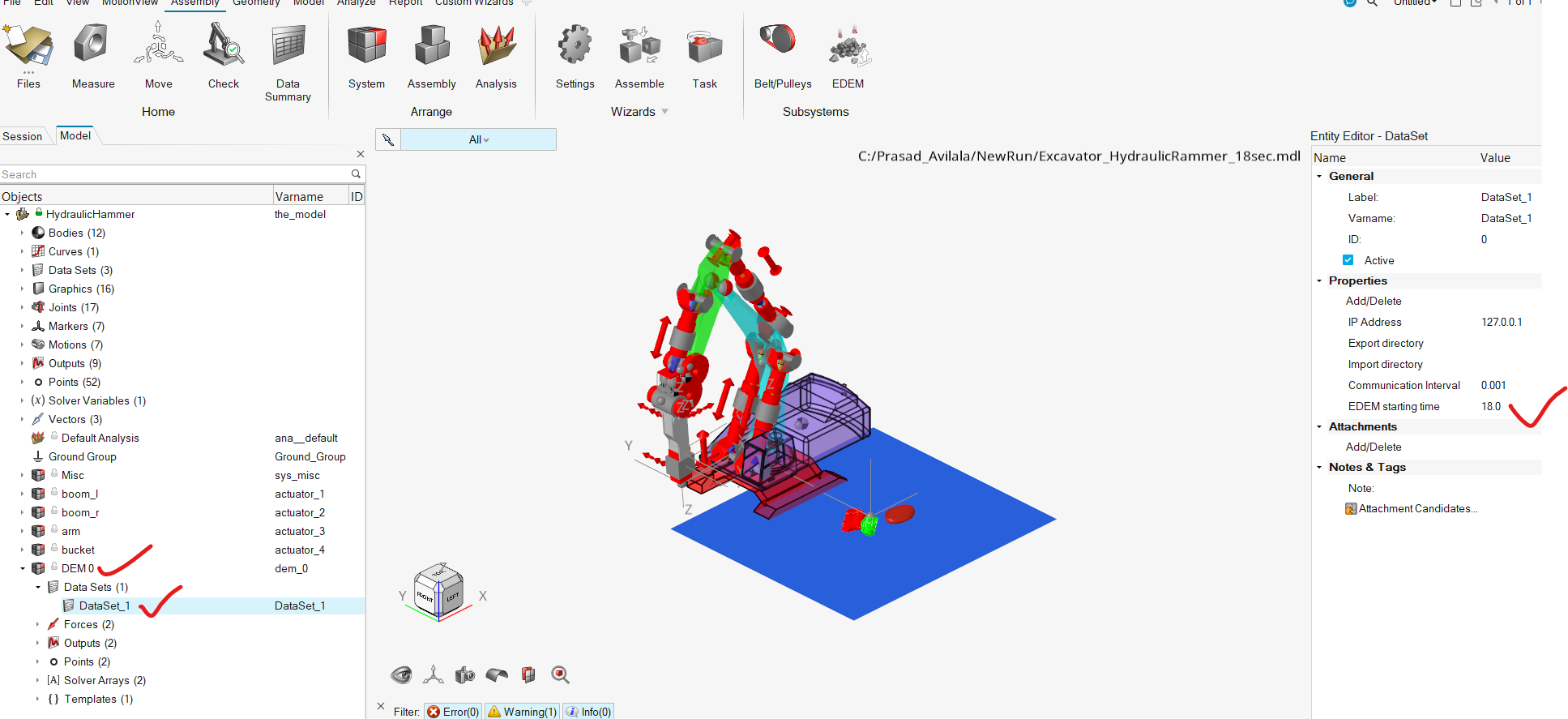

In MotionView after transferring the graphics/bodies to EDEM, there is a system by name DEM0 created (as shown in below picture) and then follow below instruction to update the coupling time step to 18sec

DEM0—> Data Sets (1)—>DataSet_1 —> EDEM starting time

EDEM Deck:

MotionSolve Setup:

Please click on below link to download, in case of any issue in downloading please comment to this link will get back to you

HydraulicHammer

CAD Files:

Summary:

Altair EDEM simulation for Hydraulic Hammer allows to:

- To Obtain the force required to break the rock

- Identify wear zones of chisel

- Find out the various joint forces

- To Access structural strength

- Perform virtual repetitive testing – under the same conditions every time

Improve performance and durability of every design - Increase accuracy compared to traditional approaches

- Avoid expensive & limiting physical prototyping Increase accuracy compared to traditional approaches

If you are looking for further information on EDEM or other Altair products we have plenty more on the Altair Community: